- Home

- >

- Products

- >

- Additive manufacturing and powder metallurgy

- >

- Sieve cleaning machines

Sieve cleaning machines

At all stages of metal powders production and handling for additive manufacturing, it is critical to ensure the chemical purity of material and to prevent cross-contamination of powders. It is particularly difficult to clean sieves with small cells (less than 100 µm) for the classification of powders. To solve this problem, Vilitek VBS-SPFD sieve cleaning machines. were developed. The system includes three machines: dual frequency ultrasonic washing machine, jet scrubbing machine and drying machine.

The main stage of sieves cleaning is carried out in ultrasonic bath. The bath is equipped with powerful industrial ultrasonic generators operating at two frequencies — 28 and 40 kHz, which provides intensive and efficient removal of particles of all sizes.

The drying machine is designed to remove moisture from the sieves after all stages of cleaning. The drying machine for sieves is equipped with diffuser systems such as an air knife, air is filtered and heated by side channel blowers before being fed to the sieves.

The drying machine is designed to remove moisture from the sieves after all stages of cleaning. The drying machine for sieves is equipped with diffuser systems such as an air knife, air is filtered and heated by side channel blowers before being fed to the sieves.

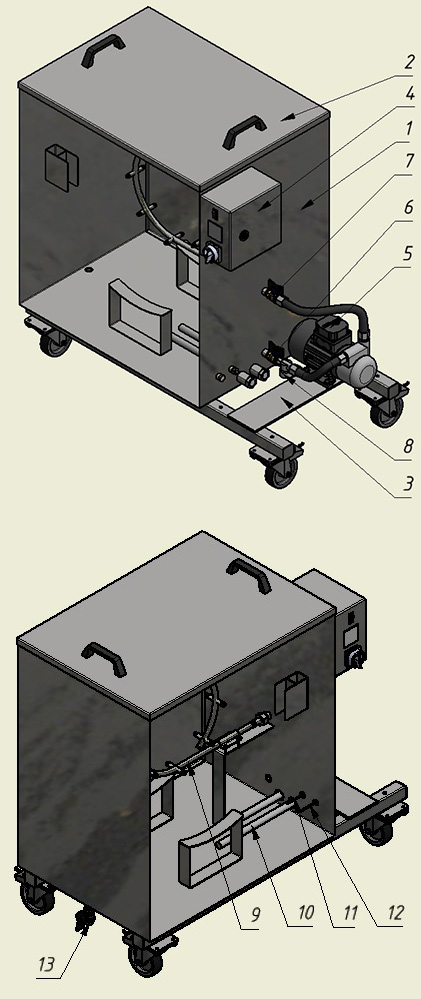

Spray rinse bath is shown in the figure to the right.

Bath pos. 1 is installed on the frame pos. 3. Frame has wheel legs with fixation. On top of the bath there is a cover pos.2. Water pump pos. 5 is fixed on the frame to the right of the bath. Pump low- and high-pressure pipelines are equipped with valves pos. 6 and 7, respectively. There is a filter pos. 8 on low-pressure pipeline which prevents large particles of powder from entering the work space of the water pump and nozzles. Inside the bath there is a sprinkler with nozzles pos. 9, heating elements pos. 10, water level sensor pos. 11, water temperature sensor pos. 11. At the bottom of the bath there is a drain valve pos. 13. Control cabinet, pos. 4, is installed on the side wall of the bath. The side wall of the cabinet is the control panel of the machine. The appearance of the control panel is shown in the figure.

Spray rinse bath control panel

|

"ON/OFF" button to switch the machine power on/off.

Temperature controller allows to set the required water temperature.

"Pump" switch to turn the water pump power on/off.

Water is pumped from the bath to the sprinkler with nozzles and washes the sieve surfaces. The water in the bath needs to be renewed periodically as it contaminated. The design features of the nozzles (wide stream opening angle) and special arrangement of the nozzles on the ring holder allow uniform distribution of the flow over the sieve surface and avoid unwashed areas.

|

Model |

Sieves diameter, mm |

|

Vilitek VBS-250SPFD |

400…600 |

|

Vilitek VBS-440SPFD |

800 |

|

Vilitek VBS-680SPFD |

1000 |

|

Vilitek VBS-980SPFD |

1200 |

|

Vilitek VBS-1500SPFD |

1500 |