- Home

- >

- Products

- >

- Additive manufacturing and powder metallurgy

- >

- Vilitek VISM-UV metal powder vacuum classifiers

Vilitek VISM-UV metal powder vacuum classifiers

We offer Vilitek VISM-600UV and VISM-800UV vacuum systems for metal powders classification in an inert gas medium with ultrasonic assisting. These systems are designed for inert-gas metal powders screening with preliminary vacuum pumping of the working chamber. Classifiers of this type are used to isolate commercial fractions of metal powders for isostatic pressing of profiled disks with blades for aircraft engines and gas turbines, additive manufacturing, powder metallurgy, and the production of powder solders.

We offer Vilitek VISM-600UV and VISM-800UV vacuum systems for metal powders classification in an inert gas medium with ultrasonic assisting. These systems are designed for inert-gas metal powders screening with preliminary vacuum pumping of the working chamber. Classifiers of this type are used to isolate commercial fractions of metal powders for isostatic pressing of profiled disks with blades for aircraft engines and gas turbines, additive manufacturing, powder metallurgy, and the production of powder solders.

Main technical parameters of the proposed equipment:

- Classifier is designed for metal powders screening with a cut point of 40-1000 µm, depending on the installed sieves.

- Classifier is equipped with a control cabinet for continuous-periodic screening that improves the output of fine powders.

- Classifier is equipped with a variable frequency drive screw feeder for accurate and repeatable feeding of screened powder.

- Classifier is designed to operate in an inert gas medium.

- Classifier is equipped with a frame, valve system for receiving powder from Vilitek BATT-100VG vacuum cylindrical tanks, it is of universal design and fits almost all metal powders transport and storage tanks.

- Number of sieves: up to 2 pcs. (screening in 3 fractions).

- Material of screening machine and metal elements that are in contact with the classified material: AISI 304 stainless steel.

- Support frame material: polymer coated structural steel.

- Classifier is prepared for use with ultrasonic resonator sieves.

- Upon delivery, a complete set of technical documentation is provided in accordance with the Russian Federation applicable standards.

Classifier is manufactured of high-quality imported and domestic components by Vilitek in Russia. If necessary, the classifier can be modified for new tasks of the Customer at any time.

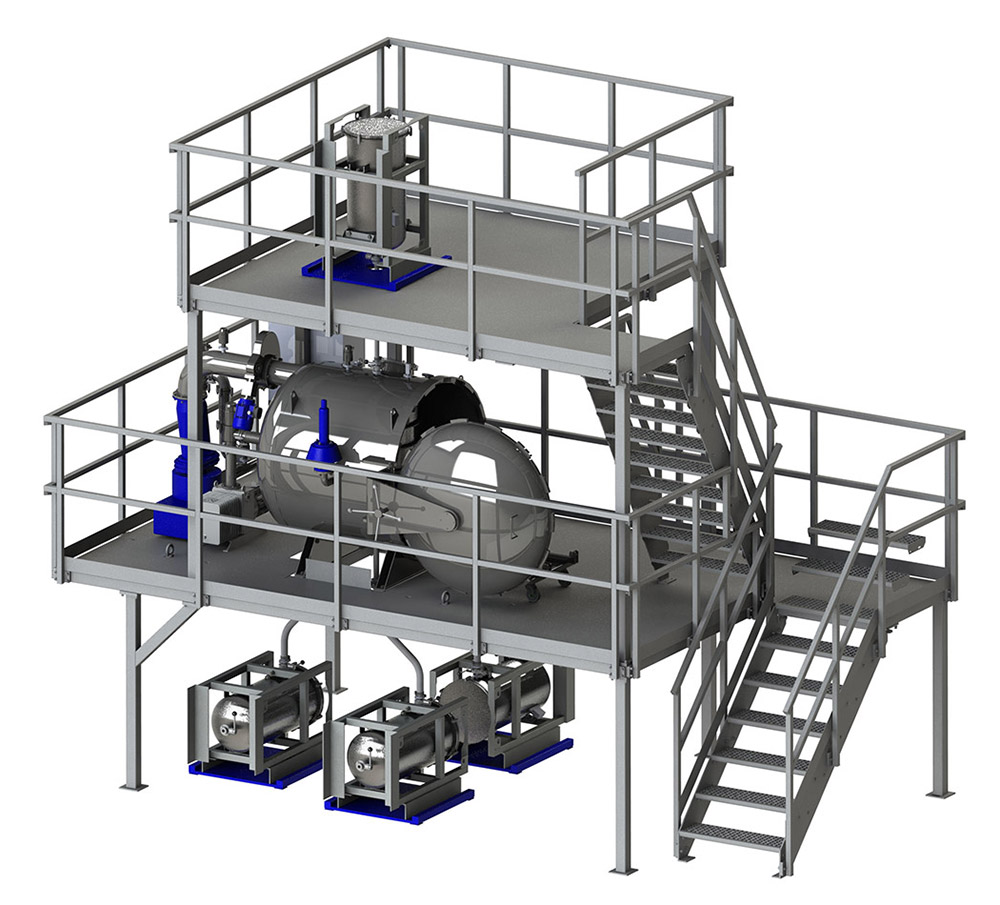

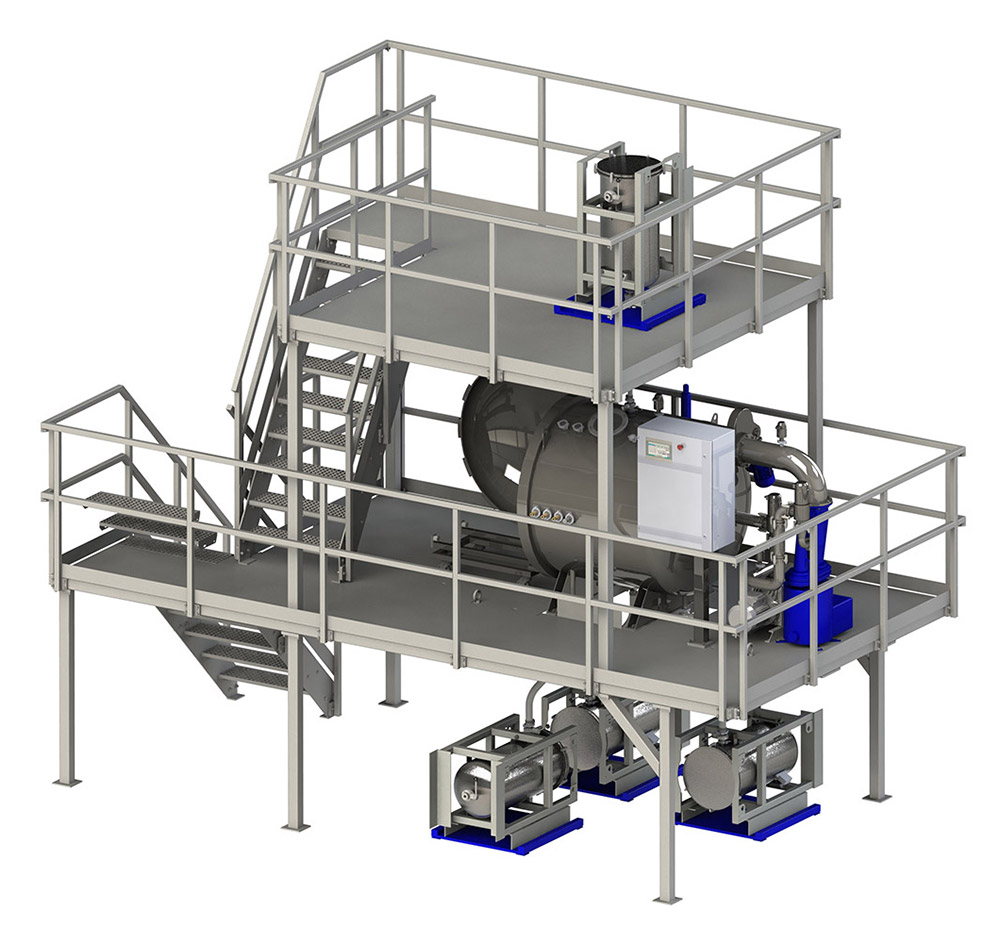

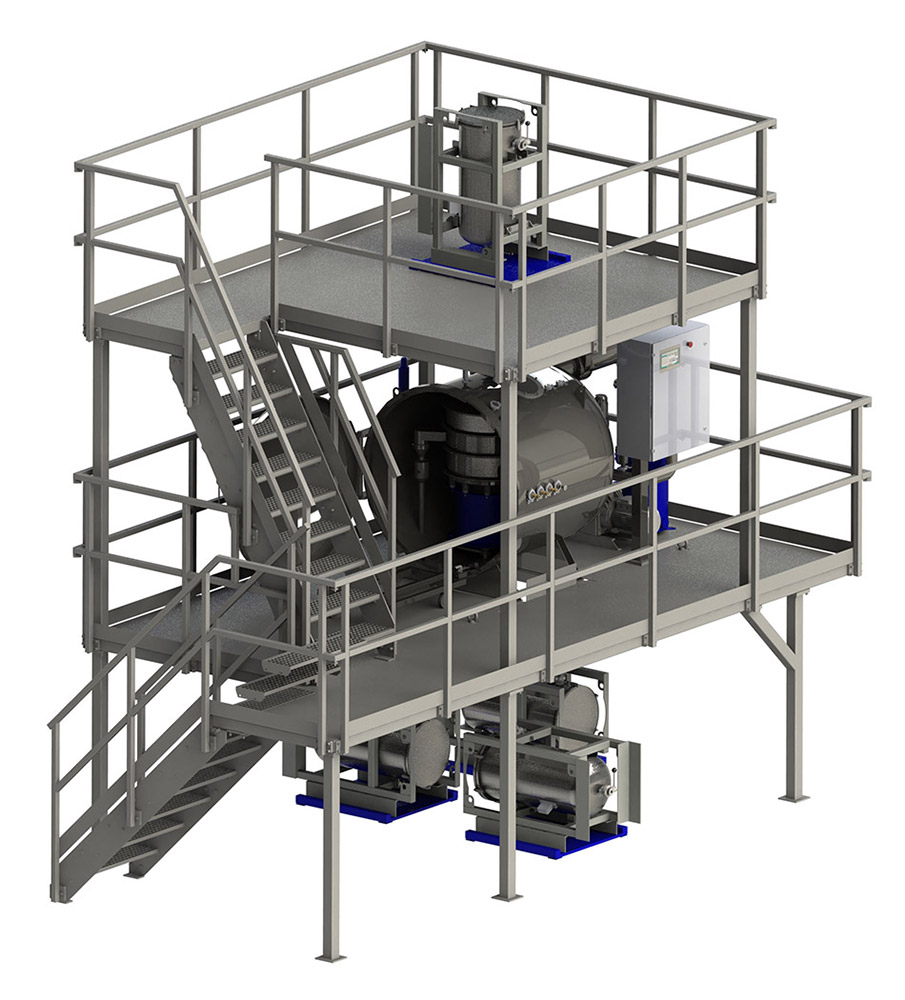

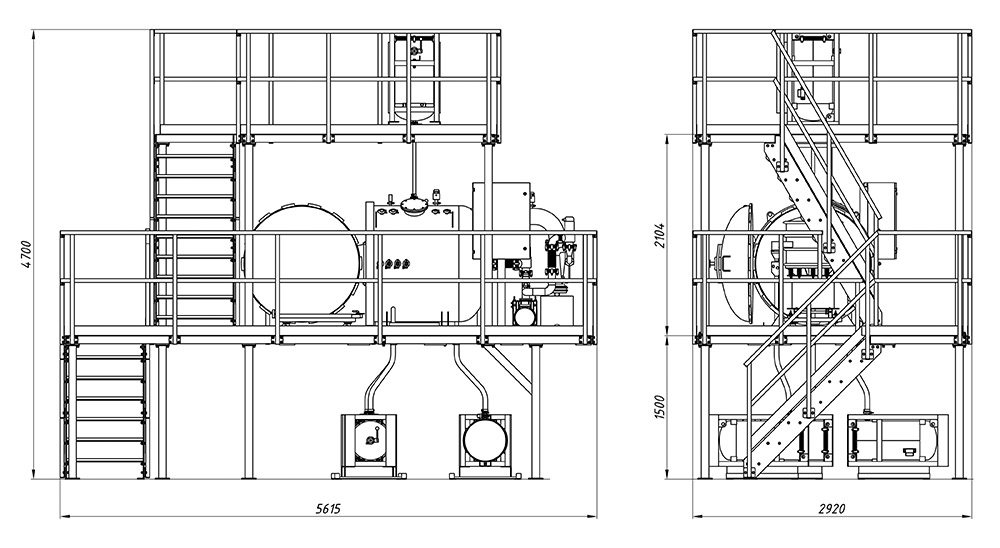

Figure and dimensional drawing of classifier

Classifier is shown in sketch, design may be specified upon the Client request during the preparation of the Offer for a specific machine.

|

|

|

|

Model |

Rated diameter of screens, mm |

Screening surface, m3 |

Typical capacity*, kg/h |

Vibration motor, W |

Centrifugal force, H |

Vibratory displacement amplitude, mm |

|

VISM-600UV Vilitek |

600 |

0,23 |

30 |

200 |

4990 |

0,8 |

|

VISM-800UV Vilitek |

800 |

0,42 |

55 |

500 |

9980 |

1,36 |

*The capacity value is based on tests performed for powder with a bulk density of 7 kg/L obtained by gas atomization, with a cut point of 60 μm, with ultrasonic screening assistance.

Technical parameters of vacuum gas system

- Ultimate vacuum in the chamber is 0.005 mm Hg.

- Maximum overpressure is 60 kPa.

- Maximum flow rate of the chamber vacuum system is 800 L/s.

Supply package:

- Vacuum chamber.

- 600 mm fine powders screening machine into three fractions with three-dimensional movement of the screens.

- Vacuum system based on a rotary vane and diffusion pump.

- System of vacuum valves and closures.

- Vacuum and positive pressure measuring system.

- Control system for pumping, checking for leaks and filling with inert gas.

- PLC-based continuous-periodical screening control system.

- Gas system (valves, pipelines, pressure reducing and flow control system).

- Ultrasonic generator for screening assistance — 2 pcs.

- Hard copy of technical documentation in Russian (2 packages).

- Sieve for ultrasonic assisting (the cell size is indicated when ordering) — 10 pcs.

- Platform scale 2,000 kg for continuous weighing of tanks during screening (integrated into control systems) — 4 pcs.

- Magnetic separators — 3 pcs.