- Home

- >

- Products

- >

- Ball mills

- >

- VBM laboratory ball mills, 14 to 80 liters

VBM laboratory ball mills, 14 to 80 liters

VBM laboratory ball mills are made by lab equipment supplier Vilitek. These ball mills are reliable and highly resourceful equipment for use in laboratories and pilot plants. VBM ball mills are designed for batch operation. They are used both for wet and dry grinding.

Vilitek VBM ball mills can grind a wide range of samples of ores and various nonmetallic materials, such as glass, ceramics, minerals, ferrous and non-ferrous ores, alloys, chemicals, vegetable stock, soils, sewage sludge, and others. VBM mills are perfectly suited for sample preparation, production of batches of materials in pilot plants, research on grindability of materials in various modes and studies using Bond technique.

The ball mill works on the following principle: size reduction is achieved by impact from metal balls in a rotating drum. The drum is loaded with grinding material and balls. When rotating, the material is crushed as a result of abrasive effect, chipping action and impact force. As a rule, the optimal grinding time, rotation speed, number and size of balls, and the grinding type are selected experimentally for each specific material – depending on its properties, quantity, and granularity of the initial fraction. At the end of the grinding cycle, the product is unloaded together with the balls into a receiving container, where they are separated. Unloading and separation can be done at the same time when using a special unloading cover, which is supplied together with each ball mill in the series.

The ball mill works on the following principle: size reduction is achieved by impact from metal balls in a rotating drum. The drum is loaded with grinding material and balls. When rotating, the material is crushed as a result of abrasive effect, chipping action and impact force. As a rule, the optimal grinding time, rotation speed, number and size of balls, and the grinding type are selected experimentally for each specific material – depending on its properties, quantity, and granularity of the initial fraction. At the end of the grinding cycle, the product is unloaded together with the balls into a receiving container, where they are separated. Unloading and separation can be done at the same time when using a special unloading cover, which is supplied together with each ball mill in the series.

|

|

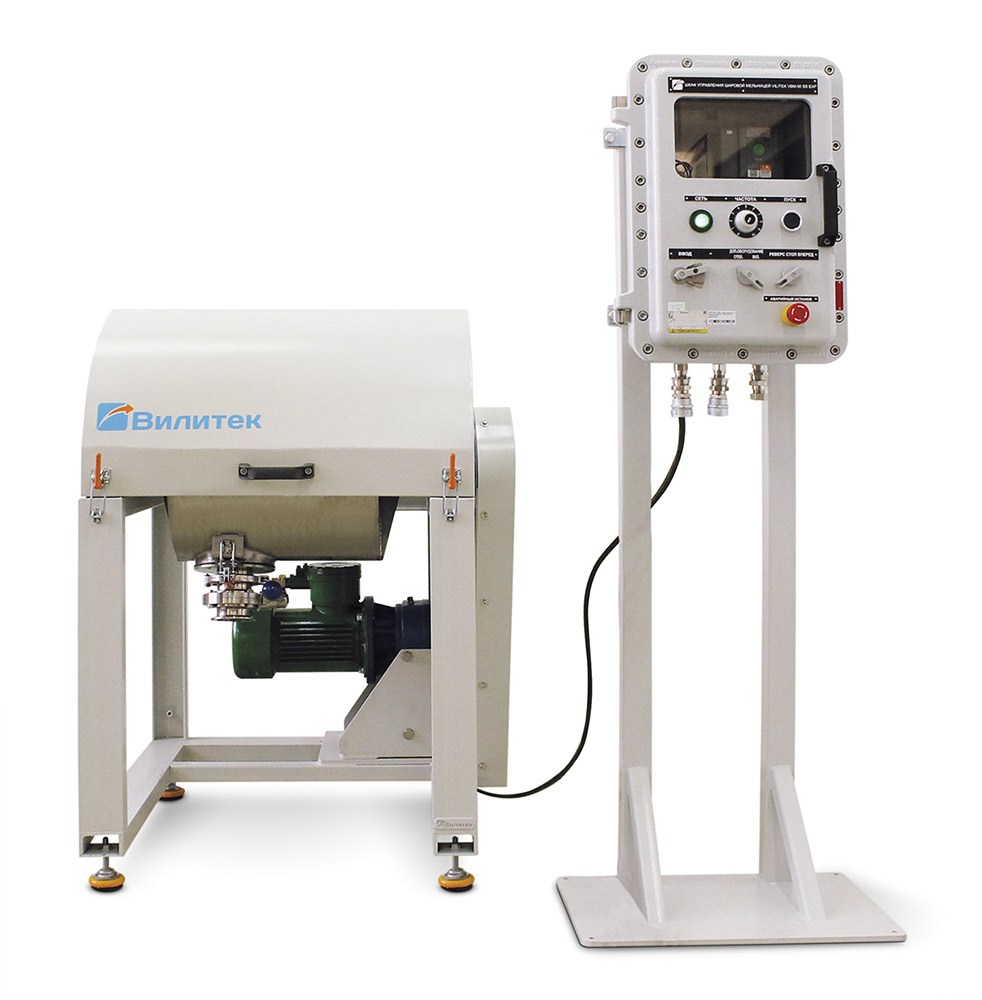

Explosion proof ball mill Vilitek VBM-50SS EXP |

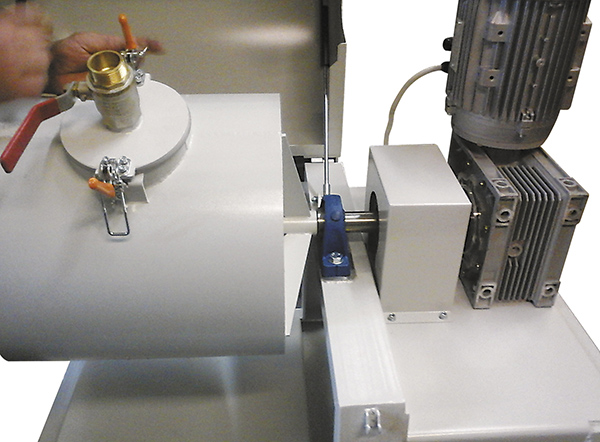

When making drums for our VBM ball mills, we use large lathes (with over 450 mm center height), which allows the shafts to turn with the drum after they are assembled, thereby ensuring high precision of rotating parts and a high bearing life. We don’t use a cantilever design in order to provide high resource and reliability to our mills. VBM ball mills are equipped with German-made top-quality industrial fittings and accessories, reliable gear motors and dust-and-moisture-proof frequency converters. VBM mills have massive and stable bases (frames) with a robust and innovative design.

When designing and manufacturing VBM mills, we pay great attention to the operator’s safety and comfort. A protective cover closes the drum during operation, which is fixed with special clamps. The weight of the protective cover when opening and closing is compensated by industrial gas springs. For horizontal installation on uneven surfaces, the mills are fitted with adjustable machine supports. Transportation is made convenient thanks to the compact size, low center of gravity and the special shape of the frame, which allows (without additional tools) to lift and mix the product using a standard hydraulic warehouse trolley (pallet jack).

|

Model |

VBM-14 |

VBM-22 |

VBM-50 |

VBM-80 |

|---|---|---|---|---|

|

Drum volume, l |

14 |

22 |

50 |

80 |

|

Speed range in grinding mode, rpm |

50-85 |

50-85 |

25-45 |

25-45 |

|

Balls diameter, mm |

15-20 |

15-40 |

15-50 |

15-70 |

|

Feedstock size, mm |

6 |

7 |

8 |

10 |

|

Maximum ball load, kg |

28 |

50 |

120 |

140 |

|

Electric motor power, kW |

0.75 |

1.5 |

1.5 |

2.2 |

|

Length, mm |

600 |

800 |

1000 |

1250 |

|

Width, mm |

600 |

800 |

800 |

800 |

|

Height, mm |

1000 |

1025 |

1025 |

1025 |

|

Weight, kg |

150 |

210 |

400 |

500 |

All our VBM mills come in two versions depending on the drum material:

N – structural steel drum.

SS – stainless steel drum.

All VBM ball mills are equipped with a dust-and-moisture-proof frequency converter (IP65 protection).