- Home

- >

- Products

- >

- Gloveboxes and accessories

- >

- VBOX CHEM chemically resistant gloveboxes

VBOX CHEM chemically resistant gloveboxes

VBOX CHEM gloveboxes are designed and manufactured by Vilitek LLC. Сasing and antechamber are made of chemically resistant polymer material. Inspection window (front panel) and access doors are made of special monolithic polycarbonate with double-sided protection against UV radiation, which is characterized by low gas permeability, reliability and long service life. The casing of this series gloveboxes is distinguished by ultra high chemical resistance to acids, alkalies, organic solvents and other corrosive liquids. Depending on the specific application, the glooveboxes can be supplied with gloves made of different materials.

VBOX CHEM gloveboxes are designed and manufactured by Vilitek LLC. Сasing and antechamber are made of chemically resistant polymer material. Inspection window (front panel) and access doors are made of special monolithic polycarbonate with double-sided protection against UV radiation, which is characterized by low gas permeability, reliability and long service life. The casing of this series gloveboxes is distinguished by ultra high chemical resistance to acids, alkalies, organic solvents and other corrosive liquids. Depending on the specific application, the glooveboxes can be supplied with gloves made of different materials.

|

|

|

VBOX CHEM 750A ECO glovebox |

VBOX CHEM 750 ECO glovebox |

VBOX CHEM gloveboxes are almost unique in the world. They are developed and manufactured in a modern facility in Russia and are also exported. The gloveboxes have a number of outstanding technical advantages:

- Maximum chemical resistance to a wide range of chemicals, not available for other manufacturers' and other series gloveboxes.

- Thanks to removable transparent front panel, there is a capability to load large items in the glovebox.

- High quality gloves manufactured by Piercan (France) are included.

- Hinges, clamps and other fittings are all industrial grade and made in Germany.

- Pressure, humidity and temperature sensors are included in the register of measuring instruments of the Russian Federation.

- High fire safety level in comparison with conventional plexiglass gloveboxes.

- LED light is included in the basic configuration.

- Wide range of options and accessories.

- Favorable price.

The main areas of use of VBOX CHEM gloveboxes:

- Working with chemically aggressive substances.

- Working with potentially dangerous mails.

- Research work and production manipulations with lithium and its compounds.

- Working with cytostatics and other dangerous medications.

- Working and experimenting with substances that require protection from atmospheric moisture or oxygen.

- Working with devices and units that require protection from atmospheric moisture or oxygen.

ECO version of VBOX CHEM gloveboxes is characterized by optimized cost and they are perfect for use in educational institutions and small laboratories. The differences between VBOX CHEM ECO and the standard VBOX CHEM gloveboxes are shown in the table below.

|

Parameter (differences only) |

VBOX CHEM ECO |

VBOX CHEM |

|

Low-pressure drop gauge in working chamber

|

Casing material is stainless steel, measuring system material is brass |

Casing material is stainless steel, measuring system material is stainless steel too |

|

Clamping mechanisms of antechamber internal door

|

Carbon steel with zinc coating made in Germany |

Surface-passivated stainless steel made in Germany |

|

Glove port diameter in basic configuration

|

186 mm |

220 mm |

|

Gloves in basic configuration

|

Latex, made in France |

Butyl rubber, made in France |

Optionally, VBOX CHEM gloveboxes can be equipped with gloves made of neoprene, butyl rubber, polyurethane, hypalon, EPDM, multilayer material (hypalon + polyurethane), and polyurethane-based

|

Model |

Working chamber (WxDxH), mm |

Antechamber (HxWxD) / access door (ø), mm |

Quantity of glove ports / gloves, pcs |

Weight, kg |

|

Without antechamber (with access door) |

||||

|

VBOX CHEM 750 Eco |

750x500x600 |

300 |

2 |

45 |

|

VBOX CHEM 750 |

750x500x600 |

300 |

2 |

45 |

|

VBOX CHEM 1000 |

1000x600x600 |

300 |

2 |

55 |

|

With antechamber |

||||

|

VBOX CHEM 750A Eco |

750x500x600 |

200х200х350 |

2 |

55 |

|

VBOX CHEM 750A |

750x500x600 |

200х200х350 |

2 |

55 |

|

VBOX CHEM 1000A |

1000x600x600 |

200х200х350 |

2 |

65 |

List of VBOX CHEM glovebox options

|

Code |

Description |

|---|---|

|

PC |

Glovebox pressure control system provides constant keeping of set pressure inside the box (± 20 mbar). It includes pressure controller with sensor and two solenoid valves. If glovebox is used to protect the product from moisture or oxygen, the system constantly maintains a slight overpressure in the box. If the box is used to work with hazardous substances, for the purpose to protect the operator, the system maintains a low vacuum in the box, which ensures maximum protection for the operator in case of system failure. To work under vacuum, it is necessary to connect the box to vacuum pump or centralized vacuum system. To work under positive pressure, as a rule, the box is to be connected to gas cylinder with valve or gas generator.

|

|

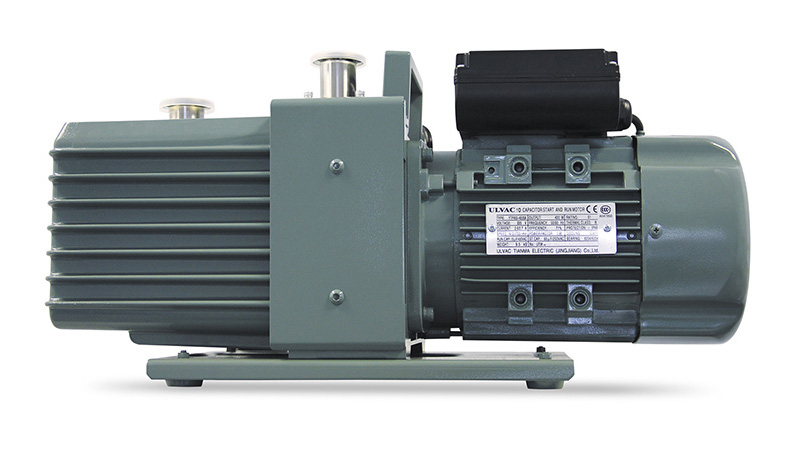

VP1 |

Diaphragm chemical resistant vacuum pump for antechambers up to 10 liters evacuation. Ultimate vacuum 10 mbar.

|

|

VP2 |

Diaphragm chemical resistant vacuum pump for antechambers up to 25 liters evacuation. Ultimate vacuum 10 mbar.

|

|

VP3 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 25 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,05 mbar. |

|

VP4 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 60 liters and main chambers up to 300 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,002 mbar.

|

|

VP5 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 120 liters and main chambers up to 600 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,002 mbar. |

|

SO |

Gas analyzer. When ordering, Customer shall specify the oxygen concentration measuring range. VILITEK gloveboxes are equipped with precision electrochemical gas analyzers with minimum response time to measure oxygen concentration. Another feature of the gas analyzers is a simple replacing and low cost of the measuring element.

|

|

SH |

Water vapor concentration sensor. It measures partial pressure of water vapor in the working chamber of glovebox.

|

|

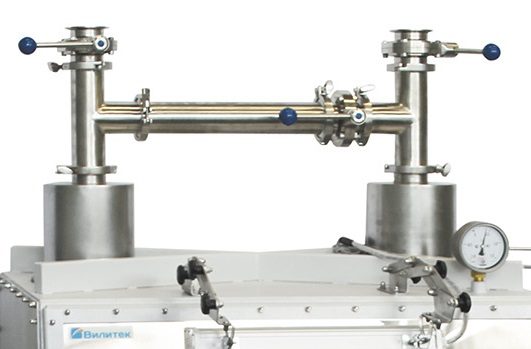

RH |

Molecular sieve water vapor trap. The molecular sieve can be regenerated by heating e.g. in a laboratory furnace.

|

|

RO |

Process gas deoxygenation system with regenerated absorber. This option includes a heating system with a temperature controller for absorber regeneration and an integrated regeneration gas flowmeter.

|

|

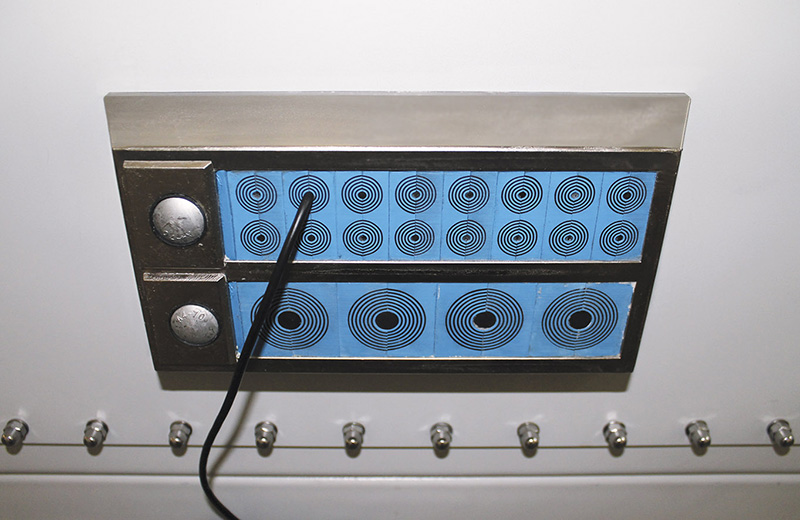

HEPA

|

HEPA-filtered gas circulation system. It is used for items that are sensitive to dust microparticles. HEPA filtration can also be used for gas sterilization in the box, as the filters used in VILITEK gloveboxes also trap microorganisms.

|

|

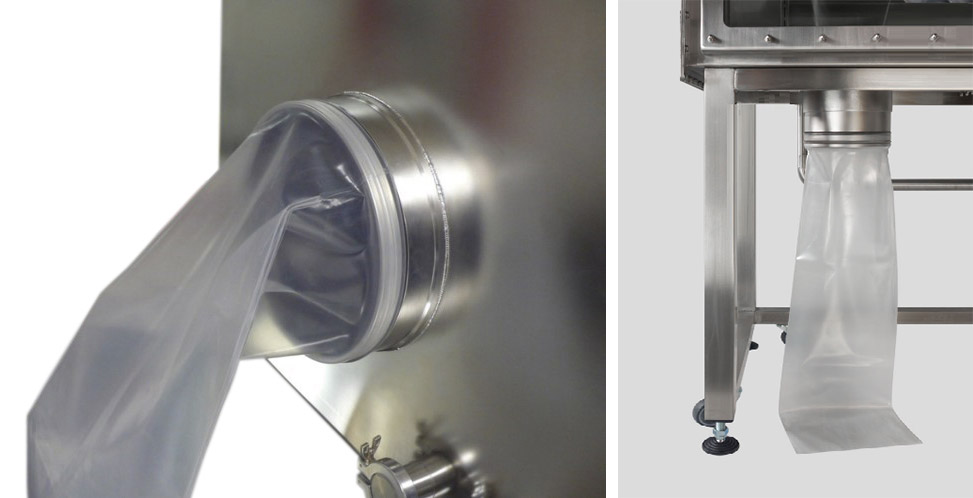

CT1 |

Optional port for collecting hazardous waste with a diameter of 186 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

CT2 |

Optional port for collecting hazardous waste with a diameter of 220 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

BASE |

Bench support for seated activity. The glovebox is normally installed on a laboratory table that can be replaced with this support. It is made of carbon steel with powder coating. |

|

BASE1 |

Bench support for standing activity. The glovebox is normally installed on a laboratory table that can be replaced with this support. Strong structure of carbon steel with powder coating. |

|

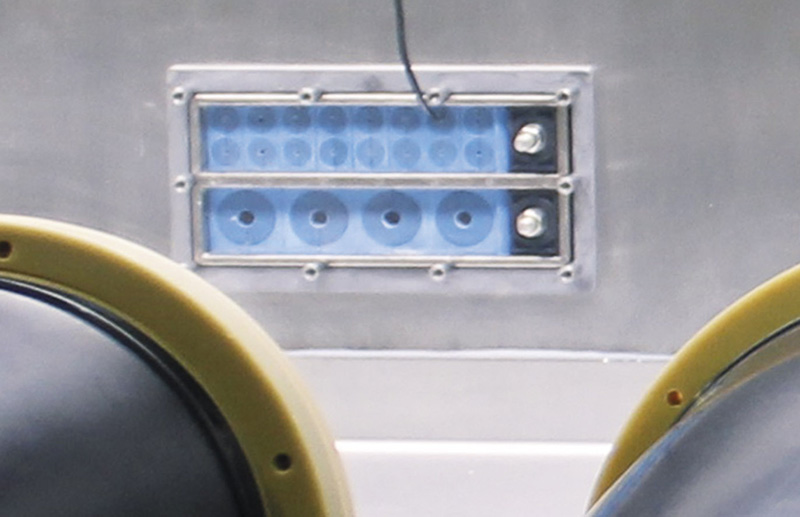

ES |

Socket kit installed inside a glovebox to plug in electric devices. The connection is made through vacuum sealed feedthrough. The maximum total current capacity is 15 A. The number of sockets is 3 pcs. Socket type: EU socket (Schuko socket, GOST 7396.1-89 type C2, type F according to CEE 7/3) with a grounding contact. |

|

EF1 |

Vacuum sealed feedthrough, 4 pins in a set with mating connectors. 2 pins with current carrying capacity of up to 10 A per pin and 2 contacts of up to 15 A per pin. The maximum total current capacity per feedthrough is up to 42 A. The maximum voltage is 560 V. Feedthrough is fixed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply; may be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox. |

|

EF2 |

Vacuum sealed feedthrough, 20 pins in a set with mating connectors. The maximum total current capacity per one pin is up to 3.5 A. The maximum total current capacity per feedthrough is up to 58 A. The maximum voltage is 560 V. Feedthrough is installed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply; may be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox. |

|

EF3 |

Feedthrough to enter round cross-section cables and tubes into the glovebox. The sealing of cable or tube is carried out on the outer diameter with special adjustable seals. Cable or tube goes into the box without breaking. Feedthrough is designed to enter of up to 16 cables or tubes with outer diameter of 3.6-16.5 mm and up to 4 cables or tubes with outer diameter of 9.5-32.5 mm into the glovebox; may not be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox.

|

|

FRM |

Gas flow measuring regulator with manual adjustment of 0.4-4 L/min. For continuous purging of glovebox with inert gas. |