VBOX-PRO gloveboxes with gas purification system

VILITEK VBOX-PRO gloveboxes are state-of-the-art and efficient equipment for carrying out work that requires high and ultra-high purification of working area from oxygen, moisture and microorganisms, protection of the operator from volatile compounds and dustlike substances. Gloveboxes are widely used for working with moisture- and oxygen-sensitive substances, devices and components. Depending on the type of substance or characteristics of the object to be worked with inside the glovebox, gloveboxes may be equipped with gloves having various chemical and physical properties, as well as with a wide range of options.

VILITEK VBOX-PRO glovebox with one side access for working with pyrophorous powdered metals.

VILITEK VBOX-PRO glovebox with four glove ports, one programmable antechamber that may be heated up to 200°C and one standard gate designed for microelectronic industry.

VILITEK VBOX-PRO glovebox with two side access and integrated heating and cooling systems

VILITEK VBOX-PRO glovebox with four glove ports

A few samples of customized VBOX-PRO gloveboxes made by our company are shown in photos. In commonly, the configuration of a particular box depends on application task. Options and standard design are described below. Custom design and options are also possible upon Customer’s technical requirement. Some more gloveboxes made by Vilitek are in Image Gallery.

A few samples of customized VBOX-PRO gloveboxes made by our company are shown in photos. In commonly, the configuration of a particular box depends on application task. Options and standard design are described below. Custom design and options are also possible upon Customer’s technical requirement. Some more gloveboxes made by Vilitek are in Image Gallery.

The purity of working area inside glovebox is achieved by physical separation of the working area from outside atmosphere and circulation of working gas through VPURE gas purification system which provides high-degree gas filtration from mechanical impurities, removing of oxygen and water vapor traces. If technological process carried out inside glovebox allows to use gas supplied in cylinders, then purification of working area in glovebox can be carried out by purging. Manipulations are carried out using gloves attached to the glove ports. When working with substances and components that are sensitive to moisture and oxygen, positive pressure in the working chamber prevents air entering from the outside even during emergency, such as when the glove is inadvertently damaged.  Working materials and devices are fed through leak-proof antechambers. This helps to minimize contamination of the working area. It is also possible to equip VBOX-PRO gloveboxes with antechambers that clean the object by vacuum and temperature, by inert gas purging, by HEPA-filtered air purging. VILITEK gloveboxes are developed and designed using modern 3D computer-modelling tools and strength calculations using finite element method. High-vacuum technology standards are used when designing and manufacturing VILITEK gloveboxes. Only high-quality materials and accessories from the best manufacturers are used in the production. Modern technologies allow for full automation of the system. To control system parameters and components, our boxes are equipped with automatic control systems featuring an intuitive and user-friendly interface, the automatic control system is part of the VPURE circulating gas purification systems.

Working materials and devices are fed through leak-proof antechambers. This helps to minimize contamination of the working area. It is also possible to equip VBOX-PRO gloveboxes with antechambers that clean the object by vacuum and temperature, by inert gas purging, by HEPA-filtered air purging. VILITEK gloveboxes are developed and designed using modern 3D computer-modelling tools and strength calculations using finite element method. High-vacuum technology standards are used when designing and manufacturing VILITEK gloveboxes. Only high-quality materials and accessories from the best manufacturers are used in the production. Modern technologies allow for full automation of the system. To control system parameters and components, our boxes are equipped with automatic control systems featuring an intuitive and user-friendly interface, the automatic control system is part of the VPURE circulating gas purification systems.

Vilitek pays special and careful attention to materials and accessories used in production. The quality of gloveboxes made by Vilitek is confirmed by the GOST R certificate of conformity.

Vilitek pays special and careful attention to materials and accessories used in production. The quality of gloveboxes made by Vilitek is confirmed by the GOST R certificate of conformity.

The main glass of standard VBOX-PRO glovebox is made of impact-resistant and scratch-resistant polycarbonate, but optionally it can be made of high-quality organic glass, triplex mineral glass, radiation-protective glass, optical filter that absorbs radiation in a given wavelength range. Gas flows in the system are controlled by high-tech vacuum and gas valves to ensure high integrity and purity of the system, all valves are made of stainless steel. The casing of VILITEK VBOX-PRO gloveboxes is made of 3 mm AISI 304 stainless steel.

The gas purification system ensures that only working gas of the desired purity is produced. This is achieved by passing the gas through absorbents. In the process, gas is purified from oxygen and moisture concentrations to below 1 ppm. The process is completely automated. The operator is only required to specify the exact value of impurity concentration within the range of the gas analizers. VPURE gas purification system is controlled by highly-accurate sensors.

Depending on the specific application, VBOX-PRO gloveboxes can be equipped with gloves made of various materials, including multi-layer gloves, gloves resistant to strong acids and alkalis, gloves resistant to ozone and ultraviolet radiation, radiation protective gloves.

VBOX-PRO gloveboxes may be supplied with the following integrated technological and research equipment:

- vacuum evaporation units;

- vacuum furnaces;

- heating and cooling units;

- freezers;

- high-vacuum freeze drying units;

- centrifugal classifiers;

- mills and crushers;

- testing screens;

- scales;

- centrifuges;

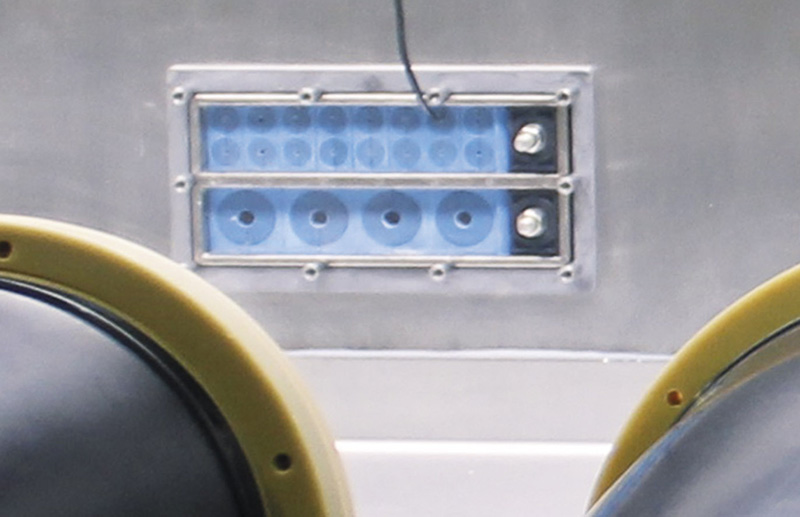

- electrical feedthroughs;

- fluid and gas inlets;

- microscopes.

Scope of supply of VILITEK VBOX-PRO glovebox

To order VBOX-PRO glovebox that is optimal for your tasks, you need to choose from the options below:

- Main chamber of the required size and configuration (one-sided or two side access).

- antechamber of the required size with demanded functions. There can be several antechambers in one box.

- VPURE circulating gas purification system up to 1 ppm of oxygen and moisture.

- Options (feedthroughs, vacuum pump, etc.).

1. Standard sizes of main chambers of VILITEK VBOX-PRO gloveboxes

Basic configuration of VBOX-PRO glovebox main chamber:

- Material: 3 mm AISI 304 stainless steel.

- Glove ports with a diameter of 220 mm made of inert wear-resistant polyoxymethylene polymer.

- Butyl rubber gloves (Piercan, France) with lock rings.

- Transparent screen (two screens for boxes with two side access) made of shock-resistant polycarbonate.

- LED lights.

- Two 1/4" free flow valves for gas supply.

- Two free flow nozzles with KF40 plugs.

- Mechanical pressure gauge to measure vacuum and positive pressure.

- Support frame made of powder-coated carbon steel.

- Wheels for moving around the room during installation.

- Adjustable damping supports for fixed installation.

Gloveboxes with one side access

|

Inner length, mm |

Inner depth (on the bottom), mm |

Inner height, mm |

Quantity of gloves, pcs |

|

1250 |

800 |

900 |

2 |

|

1500 |

800 |

900 |

3 |

|

1750 |

800 |

900 |

4 |

|

2000 |

800 |

900 |

4 |

|

1250 |

1000 |

900 |

2 |

|

1500 |

1000 |

900 |

3 |

|

1750 |

1000 |

900 |

4 |

|

2000 |

1000 |

900 |

4 |

Gloveboxes with two side access

|

Inner length, mm |

Inner depth (on the bottom), mm |

Inner height, mm |

Quantity of gloves, pcs |

|

1250 |

800 |

900 |

4 |

|

1500 |

800 |

900 |

6 |

|

1750 |

800 |

900 |

8 |

|

2000 |

800 |

900 |

8 |

|

1250 |

1000 |

900 |

4 |

|

1500 |

1000 |

900 |

6 |

|

1750 |

1000 |

900 |

8 |

|

2000 |

1000 |

900 |

8 |

VBOX-PRO glove boxes can be made to order with the dimensions of main chambers according to customer specifications and with optional equipment depending on particular application.

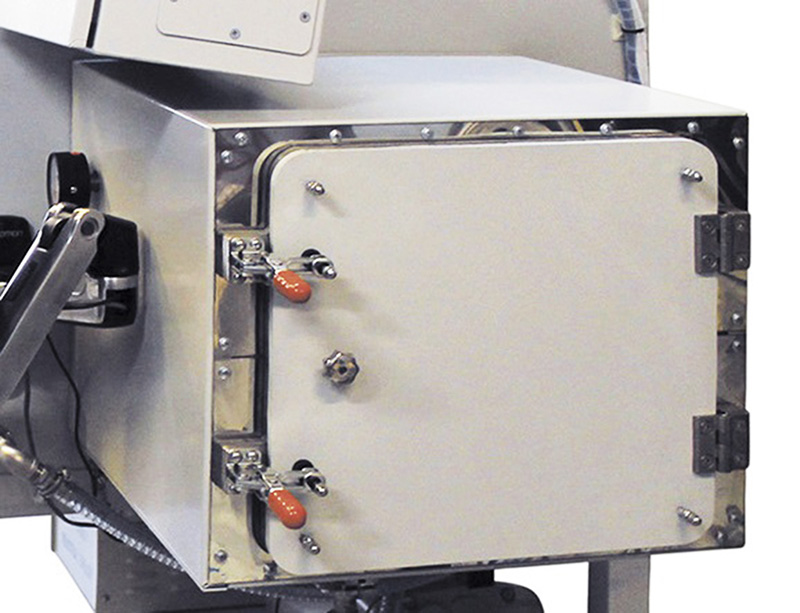

2. antechambers for VILITEK VBOX-PRO gloveboxes

Select one or several antechambers for your VBOX-PRO glovebox.

Basic configuration of antechamber for VBOX-PRO glovebox:

- Material: AISI 304 stainless steel of at least 3 mm in thickness.

- Access doors are made of anodized aluminum alloy.

- Silicone rubber seals.

- High integrity valve to inlet medium from the box.

- High integrity valve for vacuum pumping.

|

Code |

Description of antechamber, options |

|

AC1 |

Cylindrical (instrument) antechamber, internal dimensions are ø155х300 mm. Hatches are made of transparent monolithic polycarbonate, hinged. Manual inlet and pumping valve. |

|

AC2 |

Cylindrical antechamber, internal dimensions are ø200х300 mm. Hatches are made of transparent monolithic polycarbonate, hinged. Manual inlet and pumping valve. |

|

AC3 |

Cylindrical antechamber, internal dimensions are ø300х350 mm. Hatches are made of transparent monolithic polycarbonate, hinged. Manual inlet and pumping valve. |

|

AC4 |

Cylindrical antechamber, internal dimensions are ø400х400 mm. Hatches are made of transparent monolithic polycarbonate, internal hatch — with gate-type lifting mechanism, external hatch is hinged. Manual inlet and pumping valve. |

|

AC5 |

Cylindrical antechamber, internal dimensions are ø500х600 mm. Hatches are made of transparent monolithic polycarbonate, internal hatch – with gate-type lifting mechanism, external hatch is hinged. Manual inlet and pumping valve. |

|

AC6 |

Rectangular antechamber, dimensions (WxHxL) are 300х300х450 mm. Manual inlet and pumping valve. |

|

AC7 |

Manual gas inlet and pumping valve may be optionally replaced by solenoid valves. When ordering together with the VPURE system, the valve control information is displayed on the VPURE control display with the function of programming antechamber flushing cycles. |

|

AC8 |

Rectangular antechamber with infrared heating up to 200°C, controlled by PLC, internal dimensions of chamber (WxHxD) are 300x300x450 mm. Solenoid inlet and pumping valves. It allows to configurate the program of object thermo-vacuum treatment before being put in the glovebox, e.g. to remove adsorbed moisture from product surface.

|

|

AC9 |

Rectangular antechamber with infrared heating up to 200°C, controlled by PLC and from laptop, internal dimensions of chamber (WxHxD) are 300x300x450 mm. Solenoid inlet and pumping valves. It allows to configurate the program of object thermo-vacuum treatment before being put in the glovebox, e.g. to remove adsorbed moisture from product surface.

|

VBOX-PRO gloveboxes can be made to order with the dimensions of antechambers specified by the customer and with equipment depending on particular application. Silicone rubber seals can be replaced with fluorine ones. Anodized aluminum alloy access doors can be optionally replaced with stainless steel access doors.

3. VPURE circulating gas purification system up to 1 ppm of oxygen and moisture.

To obtain extra high purity of gas in the main chamber, VILITEK VBOX-PRO gloveboxes are equipped with VPURE circulating and sorption gas purification systems. These systems are designed for additional purification of gas that is fed from cylinder and is inside the glovebox from traces of oxygen and moisture. VPURE circulating gas purification system allows to maintain oxygen and moisture concentration of 1 ppm inside the glovebox. When working with the glovebox, the VPURE system also adjusts the pressure in the box, measures oxygen and moisture concentration, controls backlighting and antechamber solenoid valves (if the antechamber is ordered with integrated control function). In general, VBOX-PRO gloveboxes are equipped with VPURE 110 gas purification systems. Additionally, VPURE systems may be equipped with a gas purification from acid, alcohol and organic solvents vapors.

To obtain extra high purity of gas in the main chamber, VILITEK VBOX-PRO gloveboxes are equipped with VPURE circulating and sorption gas purification systems. These systems are designed for additional purification of gas that is fed from cylinder and is inside the glovebox from traces of oxygen and moisture. VPURE circulating gas purification system allows to maintain oxygen and moisture concentration of 1 ppm inside the glovebox. When working with the glovebox, the VPURE system also adjusts the pressure in the box, measures oxygen and moisture concentration, controls backlighting and antechamber solenoid valves (if the antechamber is ordered with integrated control function). In general, VBOX-PRO gloveboxes are equipped with VPURE 110 gas purification systems. Additionally, VPURE systems may be equipped with a gas purification from acid, alcohol and organic solvents vapors.

4. Standard options for VILITEK VBOX-PRO gloveboxes

|

Code |

Description |

|---|---|

|

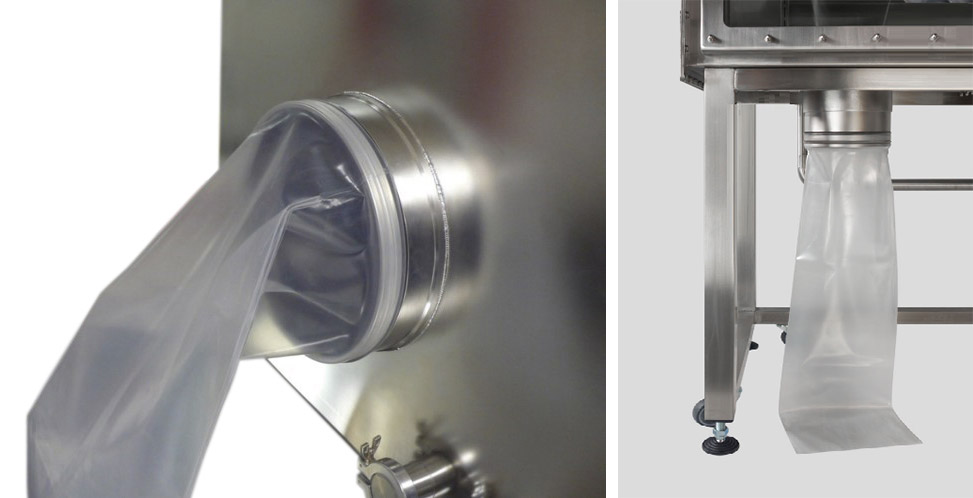

CT1 |

Optional port for collecting hazardous waste with a diameter of 186 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

CT2 |

Optional port for collecting hazardous waste with a diameter of 220 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

PC |

Glovebox pressure control system provides constant keeping of set pressure inside the box (± 20 mbar). It includes pressure controller with sensor, two solenoid valves. If glovebox is used to protect the product from moisture or oxygen, the system constantly maintains a slight overpressure in the box. If the box is used to work with hazardous substances to protect the operator, the system maintains a low vacuum in the box, which ensures maximum protection for the operator in case of system failure. To work under vacuum, it is necessary to connect the box to vacuum pump or centralized vacuum system, to work under positive pressure, as a rule, the box is to be connected to gas cylinder with valve or gas generator. This system cannot be ordered together with VPURE, since similar subsystem is a part of VPURE. |

|

SO |

Oxygen concentration sensor (gas analizer). When ordering, the oxygen concentration measuring range is to be specified. To measure oxygen concentration in VILITEK gloveboxes, high-accurate electrochemical sensors with minimal response time are used. Another feature of the used oxygen gas analizers is the replacement simplicity and low cost of the measuring probe. This sensor cannot be ordered together with VPURE, since similar subsystem is a part of VPURE.

|

|

SH |

Water vapor concentration sensor. It measures partial pressure of water vapor in the working chamber of the glovebox. This sensor cannot be ordered together with VPURE, since similar subsystem is a part of VPURE. |

|

FRM |

Gas flow measuring regulator with manual adjustment of 0.4-4 L/min. For continuous purging of glovebox with inert gas. |

|

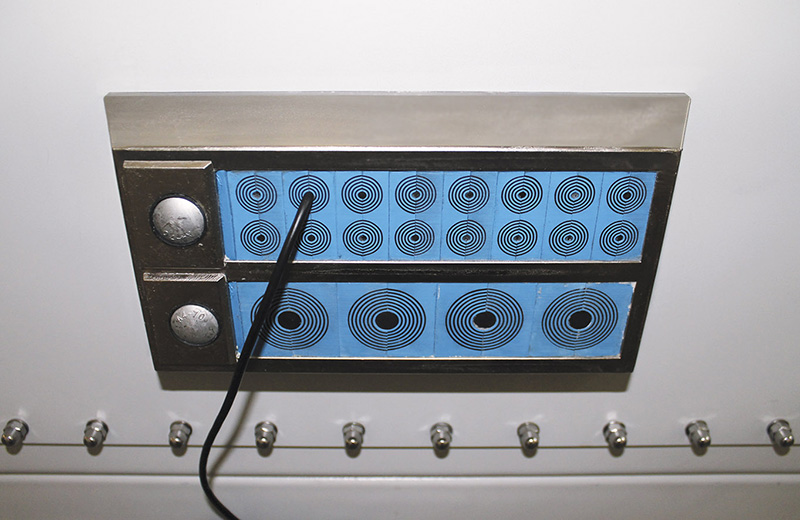

HEPA-PRO |

HEPA filtration system for VBOX-PRO gloveboxes. It includes high-efficient filter, sealed circulation fan, 3 valves to control flow (closed circulation or flow-through purging of box). |

|

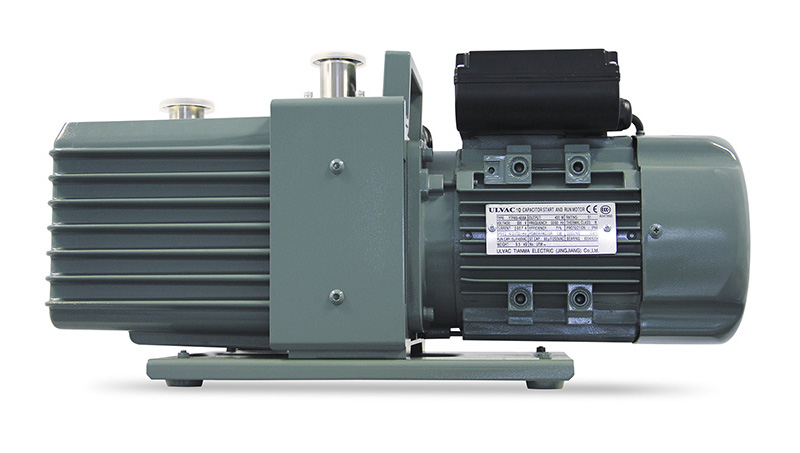

VP5 |

VPR-16 two-stage rotary vane vacuum pump. It is used to pump gas out from the antechamber when putting objects into the glovebox. The ultimate residual pressure is 0.004 mm Hg, flow rate is 240 L/min. Pump is supplied with oil mist filter. It cannot be ordered together with VPURE, since similar subsystem is a part of VPURE.

|

|

VP6 |

VPR-24 two-stage rotary vane vacuum pump. It is used to pump gas out from the antechamber when putting objects into glovebox. The ultimate residual pressure is 0.004 mm Hg, flow rate is 336 L/min. Pump is supplied with oil mist filter. It cannot be ordered together with VPURE, since similar subsystem is a part of VPURE.

|

|

CT1 |

Optional port for collecting hazardous waste with a diameter of 186 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

CT2 |

Optional port for collecting hazardous waste with a diameter of 220 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

ES |

Socket kit installed inside glovebox to plug in electrical devices. The connection is made through vacuum sealed feedthrough. The maximum total current capacity is 15 A. The number of sockets is 3 pcs. Socket type: EU socket (Schuko socket, GOST 7396.1-89 type C2, type F according to CEE 7/3) with a grounding contact.

|

|

EF1 |

Vacuum sealed feedthrough, 4 pins in a set with mating connectors. 2 pins with current carrying capacity of up to 10 A per pin and 2 contacts of up to 15 A per pin. The maximum total current capacity per feedthrough is up to 42 A. The maximum voltage is 560 V. Feedthrough is fixed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply. Several feedthroughs may be installed in one glovebox. |

|

EF2 |

Vacuum sealed feedthrough, 20 pins in a set with mating connectors. The maximum total current capacity per one pin is up to 3.5 A. The maximum total current capacity per feedthrough is up to 58 A. The maximum voltage is 560 V. Feedthrough is installed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply. Several feedthroughs may be installed in one glovebox. |

|

EF3 |

Feedthrough to enter round cross-section cables and tubes into the glovebox. The sealing of cable or tube is carried out on the outer diameter with special adjustable seals. Cable or tube goes into the box without breaking. Feedthrough is designed to enter of up to 16 cables or tubes with outer diameter of 3.6-16.5 mm and up to 4 cables or tubes with outer diameter of 9.5-32.5 mm into the glovebox. Several feedthroughs may be installed in one glovebox.

|

If you need glovebox that differs from the ones described here, e.g. equipped with any special options, then this custom box may be made to order.