- Home

- >

- Products

- >

- Gloveboxes and accessories

- >

- Stainless steel vacuum gloveboxes VBOX-SS

Stainless steel VBOX-SS vacuum gloveboxes

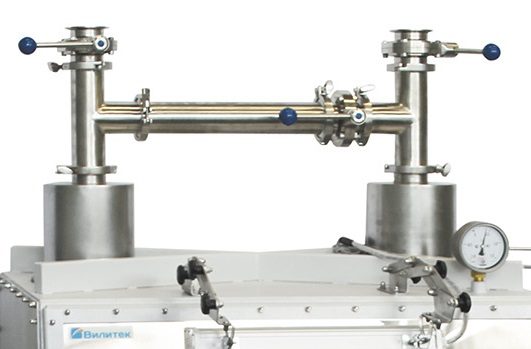

VBOX-SS gloveboxes are standardized high-quality vacuum gloveboxes made of stainless steel. They are designed for research and production. VBOX-SS gloveboxes are developed and manufactured in Russia by Vilitek LLC. Features and technical parameters are considered in VBOX-SS gloveboxes design, that distinguish them from other products. There exist 10 standard models of VILITEK VBOX-SS gloveboxes. Vacuuming of both antechamber and working chamber is available for all VBOX-SS gloveboxes. This ensures purification of the gaseous medium in the box without using expensive gas cleaning equipment. Vilitek produces a wide range of vacuum gloveboxes and glove isolators. To see photos of equipment manufactured by our company, go to gloveboxes gallery.

VBOX-SS gloveboxes are standardized high-quality vacuum gloveboxes made of stainless steel. They are designed for research and production. VBOX-SS gloveboxes are developed and manufactured in Russia by Vilitek LLC. Features and technical parameters are considered in VBOX-SS gloveboxes design, that distinguish them from other products. There exist 10 standard models of VILITEK VBOX-SS gloveboxes. Vacuuming of both antechamber and working chamber is available for all VBOX-SS gloveboxes. This ensures purification of the gaseous medium in the box without using expensive gas cleaning equipment. Vilitek produces a wide range of vacuum gloveboxes and glove isolators. To see photos of equipment manufactured by our company, go to gloveboxes gallery.

Quality of Vilitek gloveboxes is confirmed by the Certificate of Conformity with GOST.

Main areas of VBOX-SS gloveboxes use:

- Handling and experimenting with substances that require protection from atmospheric moisture or oxygen.

- Working with devices and units that require protection from atmospheric moisture or oxygen

- Gas shielded welding.

- Sealing off and assembly of parts in inert, protective or process gases.

- Handling radioactive substances.

- Handling substances dangerous to the operator.

- OLED/PLED technologies.

- Research work with Lithium batteries.

Main advantages of VBOX-SS gloveboxes:

- Simple and well-developed design ensures reliability, functionality and ease of operation.

- Several gas sources, extra sensors and other equipment may be connected due to large number of flanges, thus increasing the glovebox features.

- German-made high-quality stainless steel industrial accessories and fittings.

- Piercan (France) gloves. Piercan is the leading manufacturer of gloves for boxes.

- Wide range of accessories and options for optimized adaptation to any task.

- Made of high-quality 3 mm AISI 304 stainless steel.

The standard VBOX-SS gloveboxes are equipped with butyl rubber gloves, and 220 mm glove port for standard models and 156 mm glove port for vacuum models. These gloves are made by the reputable world leading manufacturer of gloves for boxes. Optionally, the boxes can be equipped with neoprene, latex, polyurethane, hypalon, EPDM, multilayer (hypalon + polyurethane) as well as radio-protective polyurethane-based gloves. Moreover, the glove ports can be increased to 186 mm or 220 mm. Vilitel VBOX-SS gloveboxes may be equipped with sealed feedthroughs depending on Customer requirements.

Specifications

|

Model |

Internal dimensions of working chamber (WxDxH), mm |

Internal dimensions of antechamber (WxDxH), mm |

Quantity of glove ports / gloves, pcs |

Weight, kg |

|---|---|---|---|---|

|

VBOX-SS 550 |

550x450x450 |

300х200 |

2 |

50 |

|

VBOX-SS 950 |

950x500x500 |

300х200 |

3 |

65 |

|

VBOX-SS 1150 |

1150x500x500 |

300х200 |

4 |

95 |

|

VBOX-SS 800 |

800х700х700 |

350х300 |

2 |

75 |

|

VBOX-SS 1000 |

1000х700х700 |

350x300 |

2 |

100 |

|

VBOX-SS-V 550 |

550x450x450 |

300х200 |

2 |

55 |

|

VBOX-SS-V 950 |

950x500x500 |

300х200 |

3 |

75 |

|

VBOX-SS-V 1150 |

1150x500x500 |

300х200 |

4 |

105 |

|

VBOX-SS-V 800 |

800х700х700 |

350х300 |

2 |

95 |

|

VBOX-SS-V 1000 |

1000х700х700 |

350x300 |

2 |

125 |

List of VBOX-SS glovebox options

|

Code |

Option description |

|---|---|

|

PC |

Glovebox pressure control system provides constant keeping of set pressure inside the box (± 20 mbar). It includes pressure controller with sensor and two solenoid valves. If glovebox is used to protect the product from moisture or oxygen, the system constantly maintains a slight overpressure in the box. If the box is used to work with hazardous substances, for the purpose to protect the operator, the system maintains a low vacuum in the box, which ensures maximum protection for the operator in case of system failure. To work under vacuum, it is necessary to connect the box to vacuum pump or centralized vacuum system. To work under positive pressure, as a rule, the box is to be connected to gas cylinder with valve or gas generator.

|

|

R |

Upgrade of the box with lead glass (equivalent thickness is 2.5 mm Pb) and radiation protective multilayer gloves. |

|

VP1 |

Diaphragm chemical resistant vacuum pump for antechambers up to 10 liters evacuation. Ultimate vacuum 10 mbar.

|

|

VP2 |

Diaphragm chemical resistant vacuum pump for antechambers up to 25 liters evacuation. Ultimate vacuum 10 mbar.

|

|

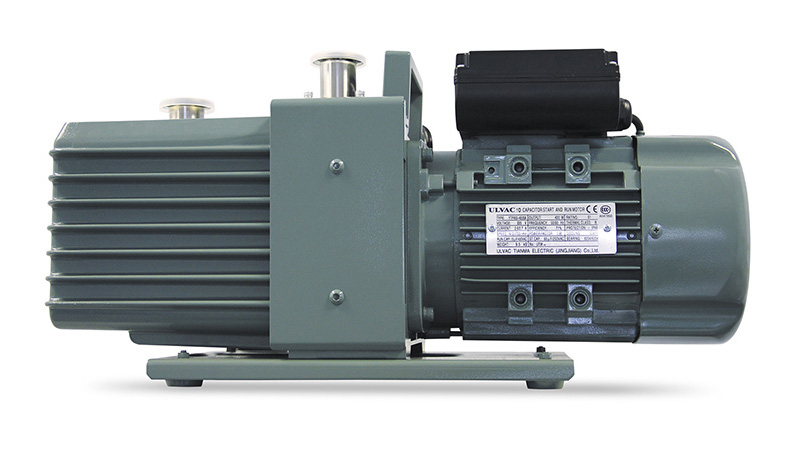

VP3 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 25 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,05 mbar. |

|

VP4 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 60 liters and main chambers up to 300 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,002 mbar.

|

|

VP5 |

Double stage oil sealed rotary-vane vacuum pump for antechambers up to 120 liters and main chambers up to 600 liters evacuation. This option is included oil mist filter. Ultimate vacuum 0,002 mbar. |

|

SO |

Gas analyzer. When ordering, Customer shall specify the oxygen concentration measuring range. VILITEK gloveboxes are equipped with precision electrochemical gas analyzers with minimum response time to measure oxygen concentration. Another feature of the gas analyzers is a simple replacing and low cost of the measuring element.

|

|

SH |

Water vapor concentration sensor. It measures partial pressure of water vapor in the working chamber of glovebox.

|

|

RH |

Molecular sieve water vapor trap. The molecular sieve can be regenerated by heating e.g. in a laboratory furnace.

|

|

RO |

Process gas deoxygenation system with regenerated absorber. This option includes a heating system with a temperature controller for absorber regeneration and an integrated regeneration gas flowmeter.

|

|

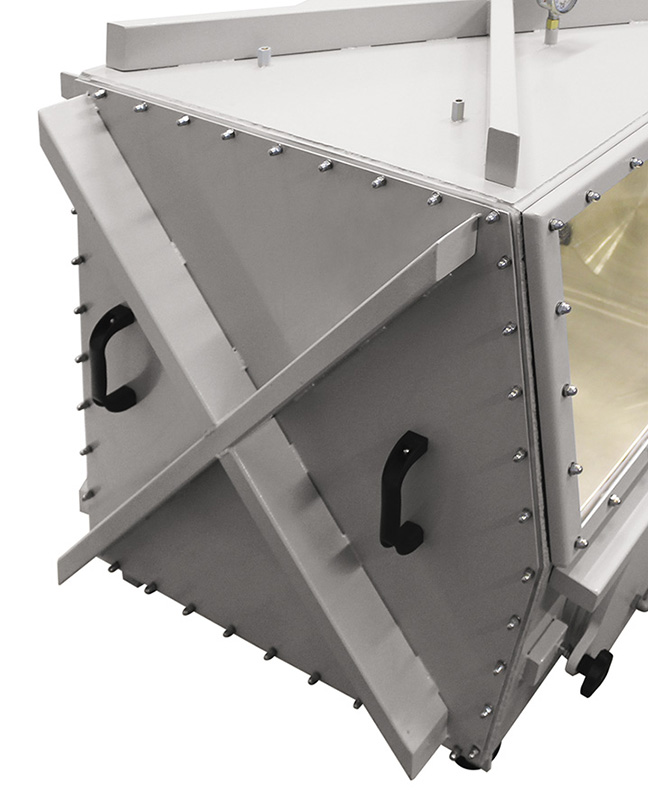

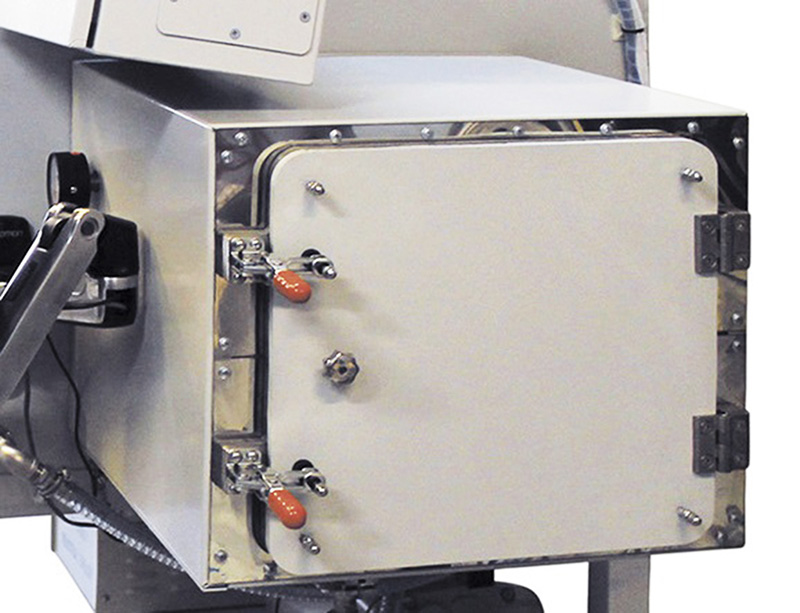

D

|

Removable side cover. This option is useful to put in and put off large items and provides for manufacturing of gloveboxes with a removable side cover, which size is of the entire side face of the box. The cover is fixed with stainless steel screws.

|

|

LC |

Replacement of antechamber with 200 mm diameter and 300 mm length by antechamber with 300 mm diameter and 350 mm length. This option is useful when handling large items. Moreover, VBOX-SS glovebox can be equipped with extended antechamber with customized dimensions. Required antechamber dimensions are specified when placing an order.

|

|

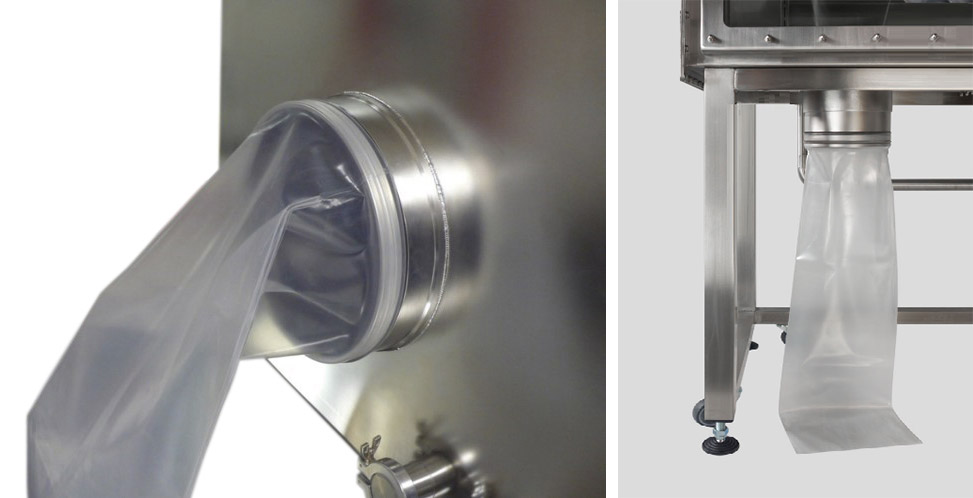

CT1 |

Optional port for collecting hazardous waste with a diameter of 186 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

CT2 |

Optional port for collecting hazardous waste with a diameter of 220 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

HEPA

|

HEPA-filtered gas circulation system. It is used for items that are sensitive to dust microparticles. HEPA filtration can also be used for gas sterilization in the box, as the filters used in VILITEK gloveboxes also trap microorganisms.

|

|

CT1 |

Optional port for collecting hazardous waste with a diameter of 186 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

CT2 |

Optional port for collecting hazardous waste with a diameter of 220 mm with hermetically welded polymer containers. It allows you to put waste when working in a box in a special sealed polymer container. There are 10 pcs containers in this set. The container welding device is sold separately. It is used when working with radioactive materials, pharmaceutical substances, etc.

|

|

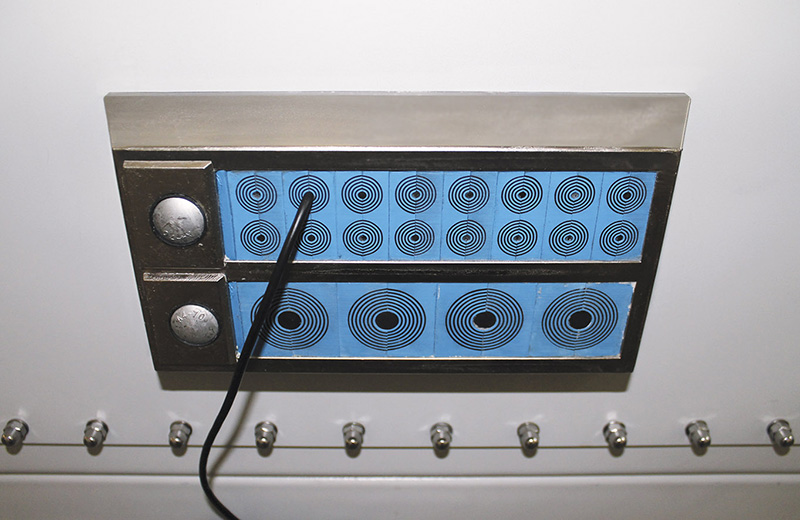

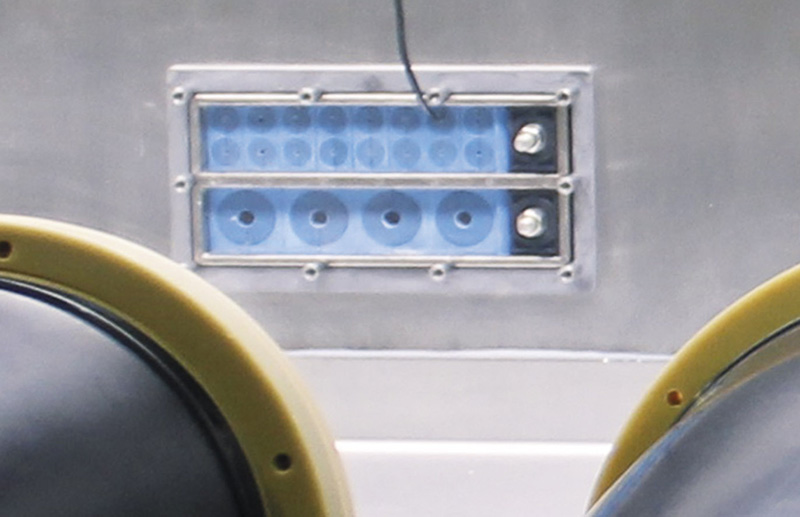

L |

Optional LED light in the working chamber.

|

|

BASE |

Bench support for seated activity. The glovebox is normally installed on a laboratory table that can be replaced with this support. It is made of carbon steel with powder coating. |

|

BASE1 |

Bench support for standing activity. The glovebox is normally installed on a laboratory table that can be replaced with this support. Strong structure of carbon steel with powder coating. |

|

ES |

Socket kit installed inside a glovebox to plug in electric devices. The connection is made through vacuum sealed feedthrough. The maximum total current capacity is 15 A. The number of sockets is 3 pcs. Socket type: EU socket (Schuko socket, GOST 7396.1-89 type C2, type F according to CEE 7/3) with a grounding contact. |

|

EF1 |

Vacuum sealed feedthrough, 4 pins in a set with mating connectors. 2 pins with current carrying capacity of up to 10 A per pin and 2 contacts of up to 15 A per pin. The maximum total current capacity per feedthrough is up to 42 A. The maximum voltage is 560 V. Feedthrough is fixed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply; may be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox. |

|

EF2 |

Vacuum sealed feedthrough, 20 pins in a set with mating connectors. The maximum total current capacity per one pin is up to 3.5 A. The maximum total current capacity per feedthrough is up to 58 A. The maximum voltage is 560 V. Feedthrough is installed on glovebox wall, there are connectors inside and outside, mating connectors are part of supply; may be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox. |

|

EF3 |

Feedthrough to enter round cross-section cables and tubes into the glovebox. The sealing of cable or tube is carried out on the outer diameter with special adjustable seals. Cable or tube goes into the box without breaking. Feedthrough is designed to enter of up to 16 cables or tubes with outer diameter of 3.6-16.5 mm and up to 4 cables or tubes with outer diameter of 9.5-32.5 mm into the glovebox; may not be used in vacuum gloveboxes. Several feedthroughs may be installed in one glovebox.

|

|

FRM |

Gas flow measuring regulator with manual adjustment of 0.4-4 L/min. For continuous purging of glovebox with inert gas. |

|

AC6 |

Rectangular antechamber with UV heating up to 200°C, PLC controlled, internal dimensions (WxHxD) are 290х265х465 mm. Solenoid inlet and pumping valves. Provides adjustment of thermo-vacuum treatment program for the item before being put into the box, for example to remove adsorbed moisture from product surface.

|

|

AC7 |

Rectangular antechamber with UV heating up to 200°C, control by PLC and notebook software, internal dimensions (WxHxD) are 290х265х465 mm. Solenoid inlet and pumping valves. Provides adjustment of thermo-vacuum treatment program for the item before being put into the box, for example to remove adsorbed moisture from product surface.

|