- Home

- >

- Products

- >

- Gloveboxes and accessories

- >

- VPURE Gas Purification Systems

VPURE Gas Purification Systems

VPURE Gas Purification Systems are designed to clean the atmosphere in gloveboxes and similar devices from oxygen and moisture traces to the values of less than 1 ppm. These systems are developed and manufactured in Russia by Vilitek LLC using state-of-the-art technologies. Chemisorption cleaning of inert gases with recoverable combined absorbers located in vacuum columns is implemented in VPURE systems. Regeneration is carried out in a fully automatic mode. When operating together with a glovebox, VPURE system also performs the following functions: oxygen concentration measurement, water vapor concentration measurement, box pressure control, box lighting system control, antechamber operation control (if antechamber is equipped with a solenoid or electro-pneumatic valves). VPURE Gas Purification Systems are developed by Vilitek, produced in the facilities located in Moscow using high quality materials and components supplied by world leading manufacturers.

VPURE Gas Purification Systems are designed to clean the atmosphere in gloveboxes and similar devices from oxygen and moisture traces to the values of less than 1 ppm. These systems are developed and manufactured in Russia by Vilitek LLC using state-of-the-art technologies. Chemisorption cleaning of inert gases with recoverable combined absorbers located in vacuum columns is implemented in VPURE systems. Regeneration is carried out in a fully automatic mode. When operating together with a glovebox, VPURE system also performs the following functions: oxygen concentration measurement, water vapor concentration measurement, box pressure control, box lighting system control, antechamber operation control (if antechamber is equipped with a solenoid or electro-pneumatic valves). VPURE Gas Purification Systems are developed by Vilitek, produced in the facilities located in Moscow using high quality materials and components supplied by world leading manufacturers.

|

|

|

|

VPURE Gas Purification Systems |

VBOX PRO glovebox with VPURE Gas Purification System |

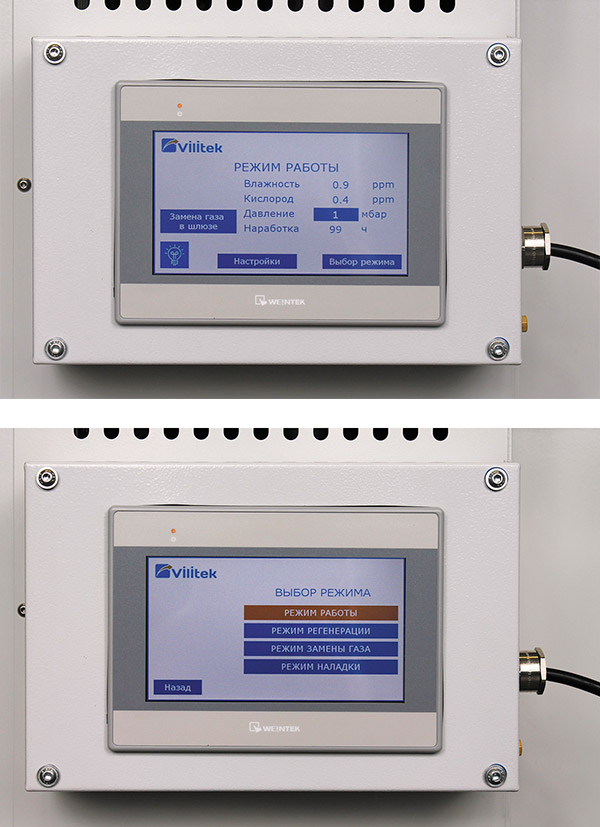

Control module with touch screen |

Features and advantages:

- Each column is heated by two independent heaters to provide high fault withstandability.

- Two independent temperature sensors on each column.

- Integrated cooling system with increased heat exchange area (10 times bigger than standard heat exchangers with size-for-size system).

- Solenoid valves are used in systems of up to VPURE 220 (compressed air or inert gas supply is not required), electro-pneumatic valves are used in system models starting from VPURE 230.

- Intelligent gas blower speed control system with feedback from oxygen and water vapor concentration sensors.

- The entire flow channel and columns are made of AISI 304 stainless steel.

- The pressure control system in the cleaned volume is active during the device regeneration.

- The portable control module with touch screen can be installed in a convenient place thanks to industrial magnets.

- Wide capabilities of customized adjustment (performed by Vilitek engineers).

- Simple user menu, maximum process automation.

Gas analyzers of oxygen and moisture are included in standard configuration and integrated to the control system.

|

|

|

|

|

VILITEK VPURE Gas Purification Systems |

System control module (bottom view) |

||

|

Model |

Number of columns, pcs |

Recommended cleaning volume, m3 |

Water-storage capacity, kg |

Oxygen capacity, L |

Attachment flange |

Gas blower flow rate, m3/h |

|

VPURE 110 |

1 |

4 |

1,5 |

40 |

KF40 |

50 |

|

VPURE 210 |

2 |

4 |

3 |

80 |

KF40 |

50 |

|

VPURE 120 |

1 |

6 |

2 |

60 |

KF40 |

100 |

|

VPURE 220 |

2 |

6 |

4 |

120 |

KF40 |

100 |

|

VPURE 230 |

2 |

15 |

5 |

170 |

ISO-K 63 |

150 |

|

VPURE 240 |

2 |

30 |

8 |

210 |

ISO-K 63 |

200 |

|

VPURE 470 |

4 |

50 |

12 |

260 |

ISO-K 63 |

200 |

|

VPURE 670 |

6 |

60 |

18 |

540 |

ISO-K 100 |

300 |

|

Model |

Absorber volume, L |

Volume of gas for regeneration, L |

Vacuum pump flow rate, m3/h |

Cooling water flow rate, L/min |

Overall dimensions, LxWxH, mm |

Weight, kg |

|

VPURE 110 |

10 |

3 000 |

10 |

1 |

815х600х770 |

145 |

|

VPURE 210 |

20 |

3 000 |

10 |

1 |

855х600х770 |

185 |

|

VPURE 120 |

20 |

4 000 |

16 |

2 |

855х600х770 |

165 |

|

VPURE 220 |

40 |

5 000 |

16 |

3 |

900х800х770 |

225 |

|

VPURE 230 |

60 |

6 000 |

24 |

5 |

1250х1000х1600 |

290 |

|

VPURE 240 |

80 |

8 000 |

24 |

8 |

1250х1250х1600 |

460 |

|

VPURE 470 |

280 |

12 000 |

24 |

8 |

2500х1250х1700 |

1450 |

|

VPURE 670 |

420 |

16 000 |

24 |

10 |

3900х1250х1700 |

2350 |