- Home

- >

- Products

- >

- Gloveboxes and accessories

- >

- Gloves for gloveboxes

- >

- Gloves for gloveboxes and isolators

- >

- Polyurethane Dry Box Gloves

Polyurethane Dry Box Gloves

Chemical composition

Chemical composition

Gloves are made of polyurethane.

Characteristics / Advantages

Excellent mechanical resistance (puncture, rupture and cut resistance).

Excellent resistance to ozone and UV.

Excellent flexibility and dexterity.

Excellent resistance to ionizing radiation influence.

Small surface area to avoid rupture and retention of powders on glove surface.

Fields of Application

Nuclear industry.

Life sciences (Pharmaceutical / Medical).

Packaging

Pair of gloves inside a reusable black pouch with layer card carton.

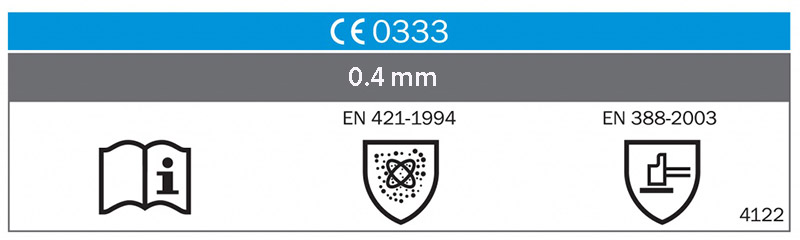

User Manual according to requirements of EU General Product Safety (CE marking) with instructions to the end user and explanations on marking on the glove and the packaging.

Storage advice

Storage condition in the original packaging must be from +5 °C to +25 °C.

Shelf life: 3 years in its original packaging.

Wash with soapy water, rinse with clean water and low temperature dry (less than +40 °C).

Glove disposal

The gloves are non-recyclable.

Classified as non-toxic waste providing they have not been contaminated during use.

|

Material code |

PUR |

|

Colour |

Blue |

|

Inner diameter of glove box port |

136, 156, 186, 220, 300 and 350 mm |

|

Hand size |

Ambidextrous or left hand / right hand |

|

Size |

Depends on model |

|

Length, mm |

750-800 (±20) |

|

Thickness, mm |

Rated: 0.4 (min: 0.3 — max: 0.6) |

|

Bead, mm |

Standard: 5 ±1 |

|

Products |

Performances* |

|

Autoclaving (+120 °C) |

- |

|

Alcohols |

- |

|

Acids, bases |

- |

|

Strong oxidizers |

- |

|

Ozone, UV, free radicals, normal aging |

+ + + |

|

Cetonic Solvents |

- |

|

Chlorinated Solvents |

- |

|

Aromatic solvents and oils |

- |

|

Aliphatic solvents and aliphatic oils |

+ + |

Temperature range: from -20 °C to +90 °C

* - Not recommended

+ Applicable in some conditions

++ Applicable

+++ Excellent for operation

|

Young modulus at deformation 100 %(1) |

Tensile strength(1) |

Elongation at break(1) |

Helium penetration(3) |

|

< 3.5 MPa |

> 50 MPa |

> 500 % |

> 70 H |

2EN 388