- Home

- >

- Products

- >

- Ultrasonic baths

- >

- Industrial ultrasonic baths 36-1,000 L

Industrial ultrasonic baths 36-1,000 L

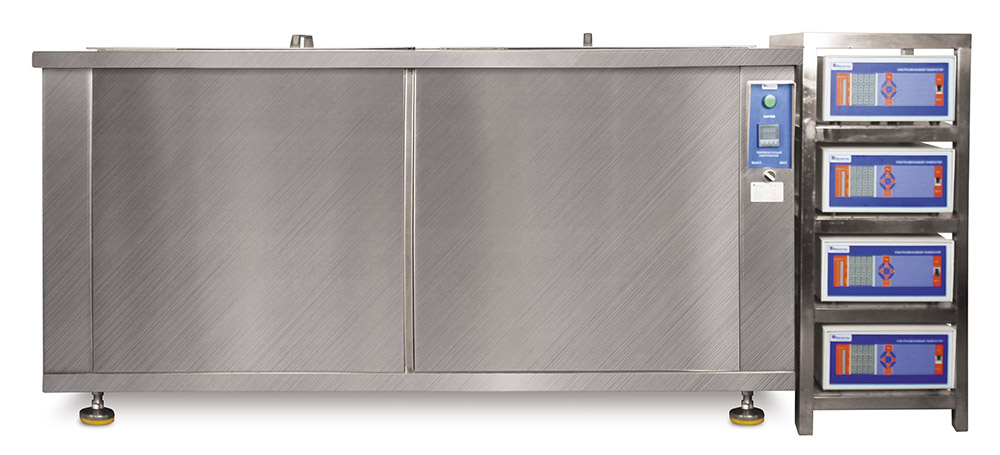

Vilitek VBS PRO ultrasonic baths are specially designed for industrial applications, have longer lasting life, and may be operated for a long time in hard operating conditions. Baths from 36 litres to 1,000 litres are serially made. We produce customized models of industrial ultrasonic washing machines of almost any volume (up to 25 cubic meters or more) with the possibility of equipping with special options according to the customer's specifications.

|

|

|

Standard ultrasonic generator |

|

|

|

|

Two-frequency ultrasonic generator |

The operating frequency of standard VBS PRO ultrasonic baths is 40 kHz, this is the optimum value for most industrial applications. We make customized ultrasonic baths with reduced and increased operating frequencies. Ultrasonic washing machines with a frequency of 28 kHz better cleans engine oil, carbon deposits, gross contaminants and can be used for heavily contaminated metal elements, for example, parts of combustion engines, castings after melting, etc. Ultrasonic washing machines with a frequency of 68 kHz, on the contrary, are better to be used for precision surfaces, for example, small microelectronic components, precision optics, etc. We recommend VBS PRO ultrasonic baths equipped with two-frequency generators for cleaning of various types of contaminants.

The working tanks of VBS PRO industrial ultrasonic baths are made of 2 mm AISI 304 stainless steel sheets. The outer casing is made of 1.2 mm thick stainless steel sheets.

Standard Vilitek VBS industrial ultrasonic baths are equipped with baskets for parts to be cleaned, working solution drain tap, and stainless steel cover.

VBS PRO baths are equipped with powerful external ultrasonic generators designed specifically for industrial applications. Vilitek generators for cleaning baths are available for operation both at one fixed frequency and with selection of one of two frequencies. All generators provide control of ultrasound power, timer function, and function of current strength measuring in transmitters. Ultrasonic generators of VBS PRO industrial baths have a frequency modulation function providing turn-on and turn-off. The mode of frequency modulation or operating frequency oscillation provide a fluctuation in the value of the actual frequency at which the ultrasound is emitted, which is of about base frequency. This mode improves the uniformity of the ultrasound in bath, prevents the occurrence of dead zones and at the same time is better for cleaning sensitive objects. Vilitek ultrasonic generators for industrial ultrasonic baths are available with frequencies of 28, 40, 68 and 100 kHz. The most commonly used generator is 40 kHz.

VBS PRO industrial ultrasonic baths provide separate power supply to ultrasonic generators and heating systems. Ultrasonic generators are powered from a single-phase 220 V grid, the heating system — from a three-phase 380 V grid. A separate power supply system provides increased reliability and the possibility of use at facilities equipped with a network with isolated neutral.

To improve the quality and speed up the washing process, we recommend using the specialized Vilitek Ultra cleaning agents for ultrasonic baths. Detergents for Vilitek ultrasonic baths are highly cost-efficient in use and transportation, as they are supplied in the form of concentrated solutions, and at the place of use they are diluted in the required concentrations with water.

VILITEK ultrasonic baths are manufactured in a modern OEM high-tech enterprise certified according to ISO 9001 quality management system standard, international safety standards, which guarantees high quality of assembly and, as a result, reliability and long equipment life. The quality and full compliance with the declared technical parameters of Vilitek VBS ultrasonic baths is confirmed by the Russian Certificate of Conformity.

VILITEK ultrasonic baths are manufactured in a modern OEM high-tech enterprise certified according to ISO 9001 quality management system standard, international safety standards, which guarantees high quality of assembly and, as a result, reliability and long equipment life. The quality and full compliance with the declared technical parameters of Vilitek VBS ultrasonic baths is confirmed by the Russian Certificate of Conformity.

Vilitek VBS industrial ultrasonic baths are used for cleaning of:

- nozzles, nozzle injectors, ejectors and similar elements of various machines;

- filters;

- combustion engines, their elements, transmission elements;

- industrial and laboratory sieves;

- valves and similar items;

- various parts, electronic and mechanical components;

- medical equipment;

- galvanic cells;

- hard-to-reach surfaces of parts when preparing for welding;

- degassing of solvents;

- elements of vacuum systems, accelerators, synchrotrons.

|

Model |

Volume, litres |

Ultrasonic power, kW |

Heating power, kW |

Quantity of ultrasonic transmitters |

Bath internal dimensions (LxWxD), mm |

Device overall dimensions (LxWxD), mm |

Gross weight, kg |

|

VBS-36 PRO |

36 |

0,6 |

2,0 |

12 |

400x300x300 |

620x520x520 |

40 |

|

VBS-60 PRO |

60 |

0,9 |

2,0 |

18 |

500x350x350 |

720x570x570 |

60 |

|

VBS-88 PRO |

88 |

1,2 |

4,0 |

24 |

550x400x400 |

770x620x620 |

75 |

|

VBS-100 PRO |

100 |

1,5 |

4,0 |

30 |

600x450x400 |

820x670x620 |

100 |

|

VBS-150 PRO |

150 |

1,8 |

6,0 |

36 |

600x500x500 |

820x720x720 |

115 |

|

VBS-175 PRO |

175 |

2,1 |

6,0 |

42 |

700x500x500 |

920x720x720 |

130 |

|

VBS-200 PRO |

200 |

2,4 |

6,0 |

48 |

800x500x500 |

1020x720x720 |

150 |

|

VBS-240 PRO |

240 |

3,0 |

6,0 |

60 |

800x600x500 |

1020x820x720 |

180 |

|

VBS-300 PRO |

300 |

3,6 |

9,0 |

72 |

1000x600x500 |

1220x820x720 |

210 |

|

VBS-500 PRO |

500 |

6,0 |

12,0 |

120 |

1200x700x600 |

1420x920x820 |

350 |

|

VBS-800 PRO |

800 |

8,0 |

15,0 |

160 |

1500x800x680 |

1720x1020x900 |

490 |

|

VBS-1000 PRO |

1000 |

10,5 |

18,0 |

210 |

1500x1000x680 |

1720x1220x900 |

630 |

The most popular industrial ultrasonic baths are in stock at Vilitek warehouse in Moscow, they can be delivered immediately after payment or signing of a supply contract.

Various special designs and options are available for Vilitek VBS industrial ultrasonic baths without a significant increase in the cost of the product, namely:

- increased or decreased frequency of ultrasound 28, 68, 80, 100 kHz etc.;

- two-frequency ultrasonic generator which provides frequencies switching and selection during operation (for example, ultrasonic baths that support operation at 28 and 40 kHz are popular);

- marine design with power supply from ship's electrical grid;

- elevator, service lift for heavy products to be put inside bath;

- oil-free compressor with an air gun for products blowing and drying after ultrasonic cleaning;

- rack for ultrasonic generators, and frame with wheel supports;

- customized ultrasonic baths.