Analyzers of protein, fat, fiber and moisture concentration

Vilitek company supplies laboratory apparatuses, systems and analyzers of protein, fat and fiber concentration in various food products and animal feed. Our devices may be also used to measure the nitrogen content in soil and fertilizers. We aim to ensure our equipment to be user friendly and as convenient in operation as possible, but at the same time it should significantly reduce the analysis labour intensity and be budget-friendly for most laboratories and enterprises.

Since 1883 and by this day, the Kjeldahl method has been being the main method for the quantitative measurement of total and residual nitrogen in organic samples. This method is sufficiently accurate and relatively simple, it is as follows:

Kjeldahl method

An organic weightened sample is taken. Its accuracy is measured by laboratory scales. If the sample is solid, it is recommended to grind it by special laboratory mills to speed up the process. The prepared material is placed in a flask.

Separation of nitrogen compounds from the sample and their conversion to ammonium sulfate is carried out by the method of wet oxidation. Concentrated sulfuric acid and a catalyst are to be added to the flask. When heated, the sample is destructed. The solution obtained at this stage is unsuitable for analysis. Therefore, nitrogen sulfate is transferred to ammoniation mode by adding alkali.

In order to separate nitrogen compounds for analysis, they are distilled off in the form of ammonia by vapor in a distiller, and collected in a separate flask. There is a definite volume of sulfuric or boric acid with a given concentration. For example, according to the National Standard of the Russian Federation to measure the non-protein nitrogen in milk and dairy products, boric acid is used to analyze dairy samples. Ammonia collected in the flask after distillation converts to ammonium sulfate or borate.

The final step in the analysis is alkali titration of the resulting compound for excess acid. In parallel, the initial volume used in the analysis of the pure reagent is titrated. Based on the difference in alkali spent on titration of the sample and the basic reagent, the amount of nitrogen is calculated. The percentage of total protein is measured by multiplying the amount of nitrogen by 6.25.

Modern laboratory equipment allows to speed up and simplify the analysis by the Kjeldahl method. AKV-20 Kjeldahl apparatus is designed to distill the sample and prepare the material for titration. In automatic mode, the distillation of one sample takes no more than 5-10 minutes. Manual control is provided for special parameters with adjustment of a distillation time of up to 1 hour. Automatic cleaning of the apparatus systems allows for high measurement accuracy. An integrated cross protection system is provided for emergency to exclude equipment failure.

Reagents are prepared in AKV-20 apparatus step-by-step, the concentrated acid is pre-dissolved, and the alkali is added in small amounts during slaking. This mode allows to avoid violent exothermic reactions.

Laboratory device designed for samples wet oxidation is called a digester. Various materials are degraded in digester for further analysis. As an example is the mineralization of organic samples for research by Kjeldahl method. Vilitek PMP digester can be integrated in the device used for measuring the nitrogen quantitative content in biomaterials. But for the next stage of the Kjeldahl analysis, digesters must be used together with VILITEK AKV-20 Kjeldahl apparatus. The sample is heated by infrared rays from a graphite or aluminum module. In this case, heating of material to be incinerated occurs immediately, without the heating of the container in which it is located.

PMP digestors can be used to handle several samples simultaneously. Depending on digester design, the heating block can be made of aluminum alloy or graphite. Heaters upper temperature limits are 500 °C and 650 °C, respectively. To collect acid gases during mineralization, a digestion module for gas collection is used together with PMP digestor. Module gas offtake capacity is from 5 to 30 L/min. The number of holes is the same as the number of heating spots in the digester (20/12/8).

Vilitek fiber analyzer is used to degrade samples and measure fiber content. The apparatus operation cycle includes: sample hydrolysis (alkaline or acid), washing and filtering. Three heating routes (acid, alkali, distilled water) may be set and controlled separately. Programming of all processes in apparatus. Simultaneous handling of 6 samples.

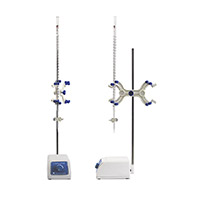

Soxhlet extractor

In 1879 Franz von Soxhlet developed a glass apparatus for laboratory extraction analysis of hardly soluble substances. A volatile solvent is poured into a round flask. Soxhlet extractor is installed on the flask through ground-glass joint. There is a reflux condenser at the top of extractor, underneath there is a glass in which the substance to be extracted is placed. A glass is connected to the bottom flask by siphon.

Additionally, the flask is connected to the reflux condenser with a side tube. When the solvent is heated, its vapors rise in tube into a reflux condenser, where they condense and drain into a glass. The extracted substance is dissolved in a glass. When the glass is completely filled, the solvent is drained into the lower flask. The process continues until complete extraction of basic substance. At the end of the extraction, the solvent is distilled off.

Soxhlet’s modern laboratory apparatuses retained the name and principle of operation of the extractor of the same name, but they completely changed and became automated. ASV-6 Soxhlet apparatus is designed for fat content analysis. In automatic mode, the device performs all the functions of Soxhlet glass extractor: heating, condensation, absorption, separation, chemical degradation and solvent recovery. It can be used to work simultaneously with 6 samples. The security system, in case of deviation from the normal mode, provides a light, sound and text warning.