- Home

- >

- Products

- >

- Gloveboxes and accessories

- >

- Gloves for gloveboxes

- >

- Sleeves for isolators

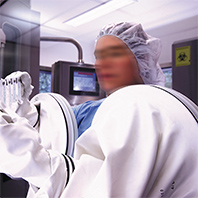

Sleeves for isolators

The idea of the need for isolators appeared in the late 20-ies of the last century. This is due to attempts to breed animals free of microorganisms. The first steam isolator was metal. Today there are many varieties of isolators made of modern materials.

The isolators are currently applicable with the development of biomedical industries that require sterile conditions. To keep rooms clean requires a lot of expenses. It is often much more profitable to use isolators. Their equipment depends on the application. If the contents of the isolators should not penetrate outside and have an impact on the person, then a reduced pressure is created inside the isolator. If the processed materials have already been sterilized and are critical to external influences, the isolator is maintained positive pressure.

Sufficient access to each point of the interior space and freedom of movement for operator are required for work in the isolators. This is facilitated by the sleeves fixed in special ports. Under different environments and substances, with which the work is carried out, sleeves of different polymeric materials are used.

Natural rubber sleeves

Natural rubber sleeves are suitable for work at wide temperature range. At -40 °C the material keeps its elasticity. Works with acids and alkalis, alcohols and esters are admissible. Latex destruction is in ozone and under impact of salts or hydrocarbons with strong oxidizing properties.

They are used in pharmaceuticals and medicine.

Neoprene sleeves

Polychloroprene is used in aggressive environments. It is resistant to UV, ozone and does not sustain combustion. The main purpose of neoprene sleeves is to work in oily media. Good resistance to concentrated bases and acids, strong oxidizers. Polychloroprene is not applicable with halogens, hydrocarbons and esters.

They are used in the nuclear industry.

CSM sleeves

Chlorosulphonated polyethylene differs by high chemical resistance to oxidants such as Н2О2. CSM sleeves are good resistant to γ, β and UV radiation as well as ozone.

They are used in pharmaceuticals and medicine.

Black EPDM rubber sleeves

Black EPDM rubber acts well at temperatures from -50 °C to +150 °C, steam treatment is allowed up to +180 °C. Resistance to ozone and UV radiation.

It is not intended for use with mineral and vegetable oils. The content of carbon dust in the material makes it unsuitable for use as electrical insulation, but the sleeves do not accumulate static charge.

They are used in pharmaceuticals and medicine.

Polyurethane and CSM sleeves

Purposefully sleeves for isolators can be made two-layered. The inner layer is of polyurethane rubber and provides high elasticity, and the outer layer is of chlorosulfonated polyethylene and protects against strong oxidants and various types of radiation.

They are used in pharmaceuticals and medicine.